对SPI进行参数化结构设计

Posted kingstacker

tags:

篇首语:本文由小常识网(cha138.com)小编为大家整理,主要介绍了对SPI进行参数化结构设计相关的知识,希望对你有一定的参考价值。

前言

为了避免每次SPI驱动重写,直接参数化,尽量一劳永逸。

SPI master有啥用呢,你发现各种外围芯片的配置一般都是通过SPI配置的,只不过有3线和四线。

SPI slave有啥用呢,当外部主机(cpu)要读取FPGA内部寄存器值,那就很有用了,fpga寄存器就相当于RAM,cpu通过SPI寻址读写数据。

代码仅供参考,勿做商业用途。

SPI salve

SPI salve支持功能:(1)支持三线SPI或者四线SPI。通过define切换。

(2)支持指令长度、帧长自定义。

(3)工作时钟可自定义,大于SPI clk的2倍。

用户只需修改:(1)几线SPI。(2)单帧长度。(3)指令长度。(4)寄存器开辟。

注意:指令最高bit表示读写,低写高读,其余bit表示地址。指令接着为数据端,两者位宽之和即为SPI单帧长。

//`define SPI_LINE //是否是三线SPI `define SPI_FRAME_WIDTH 16 //SPI一帧长度为16 `define SPI_INS_WIDTH 8 //SPI指令长 `timescale 1ns/1ps //// module spi_slave ( input i_clk , //work clk input i_rst_n , input i_spi_clk , //SPI clk input i_spi_cs , //SPI cs `ifdef SPI_LINE //条件编译 inout io_spi_sdio `else input i_spi_mosi , //SPI mosi output o_spi_miso //SPI miso `endif ); //位宽计算函数 function integer clogb2 (input integer depth); begin for (clogb2=0; depth>0; clogb2=clogb2+1) depth = depth >>1; end endfunction reg r_cs = 1‘b1; //打一拍 always @(posedge i_clk) begin r_cs <= i_spi_cs; end reg [1:0] r_spi_clk_edge = 2‘b00; //SPI clk边沿检测 always @(posedge i_clk) begin r_spi_clk_edge <= r_spi_clk_edge[0],i_spi_clk; end //always reg [clogb2(`SPI_FRAME_WIDTH-1)-1:0] r_spi_cnt = ‘d0; always @(posedge i_clk) begin if (r_cs) //cs为高则归零 r_spi_cnt <= ‘d0; else if (r_spi_clk_edge == 2‘b10) //下降沿才计数 r_spi_cnt <= r_spi_cnt + ‘d1; end ////指令锁存 reg [`SPI_INS_WIDTH-1:0] r_ins = ‘d0; always @(posedge i_clk) begin if ((~r_cs) && (r_spi_clk_edge == 2‘b01)) //上升沿锁存数据 begin if ((r_spi_cnt >= 0) && (r_spi_cnt <= `SPI_INS_WIDTH-1)) `ifdef SPI_LINE //条件编译 r_ins <= r_ins[`SPI_INS_WIDTH-2:0],io_spi_sdio; `else r_ins <= r_ins[`SPI_INS_WIDTH-2:0],i_spi_mosi; `endif end end ////数值写入 reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_data_rx = ‘d0; always @(posedge i_clk) begin if ((~r_cs) && (r_spi_clk_edge == 2‘b01)) //上升沿锁存数据 begin if (r_spi_cnt >= `SPI_INS_WIDTH) `ifdef SPI_LINE r_data_rx <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],io_spi_sdio; `else r_data_rx <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],i_spi_mosi; `endif end end ////用户寄存器定义 reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_reg0 = ‘d0; reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_reg1 = ‘d0; reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_reg2 = ‘d0; reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_reg3 = ‘d0; //// always @(posedge i_clk,negedge i_rst_n) begin if (~i_rst_n) begin r_reg0 <= ‘d0; r_reg1 <= ‘d0; r_reg2 <= ‘d0; r_reg3 <= ‘d0; end else if ((~r_ins[`SPI_INS_WIDTH-1]) && (r_spi_cnt == (`SPI_FRAME_WIDTH-1)) && (~r_cs) && (r_spi_clk_edge == 2‘b01)) begin `ifdef SPI_LINE case (r_ins[`SPI_INS_WIDTH-2:0]) ‘d0:begin r_reg0 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],io_spi_sdio; end ‘d1:begin r_reg1 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],io_spi_sdio; end ‘d2:begin r_reg2 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],io_spi_sdio; end ‘d3:begin r_reg3 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],io_spi_sdio; end endcase `else case (r_ins[`SPI_INS_WIDTH-2:0]) ‘d0:begin r_reg0 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],i_spi_mosi; end ‘d1:begin r_reg1 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],i_spi_mosi; end ‘d2:begin r_reg2 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],i_spi_mosi; end ‘d3:begin r_reg3 <= r_data_rx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],i_spi_mosi; end endcase `endif end end ////寄存器值读出 reg [`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1:0] r_data_tx = ‘d0; always @(posedge i_clk) begin if (r_ins[`SPI_INS_WIDTH-1] && (~r_cs) && (r_spi_clk_edge == 2‘b10)) begin if (r_spi_cnt == (`SPI_INS_WIDTH-1)) begin case (r_ins[`SPI_INS_WIDTH-2:0]) ‘d0:begin r_data_tx <= r_reg0; end ‘d1:begin r_data_tx <= r_reg1; end ‘d2:begin r_data_tx <= r_reg2; end ‘d3:begin r_data_tx <= r_reg3; end endcase end else r_data_tx <= r_data_tx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-2:0],1‘b0; end end ////读取输出 `ifdef SPI_LINE assign io_spi_sdio = (r_ins[`SPI_INS_WIDTH-1]) ? (((r_spi_cnt>=`SPI_INS_WIDTH) && (r_spi_cnt<`SPI_FRAME_WIDTH)) ? r_data_tx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1] : 1‘bz) : 1‘bz; `else assign o_spi_miso = ((r_spi_cnt>=`SPI_INS_WIDTH) && (r_spi_cnt<`SPI_FRAME_WIDTH)) ? r_data_tx[`SPI_FRAME_WIDTH-`SPI_INS_WIDTH-1] : 1‘b0; `endif endmodule // end the spi_slave model

SPI master

spi master内部仅仅封装SPI驱动,写入值读出控制由上层控制,这部分逻辑很simple,不赘述。用户只需给入SPI帧及控制使能即可。

用户只需修改parameter参数:(1)单帧长。(2)指令长。(3)数据长。(4)工作时钟。(5)SPI clk。

实现不使用状态机,采用线性序列计数法。

//`define SPI_LINE //是否是三线SPI `timescale 1ns/1ps module spi_master #(parameter p_spi_frame_width = 16, //SPI单帧长度 parameter p_spi_ins_width = 8 , //指令长度 parameter p_spi_data_width = 8 //读出数据长度 ) ( input i_clk , //系统时钟 input i_rst_n , input i_flag , //检测到flag的上升沿则启动一次传输,一个时钟周期即可 input [p_spi_frame_width-1:0] i_spi_data , output o_spi_cs , output o_spi_clk , `ifdef SPI_LINE //条件编译 inout io_spi_sdio , `else input i_spi_miso , //SPI miso output o_spi_mosi , //SPI mosi `endif output o_transfer_done , //单次传输完成 output [p_spi_data_width-1:0] o_spi_data //读取数据 ); parameter p_clk_fre = 200; //XXM时钟频率 parameter p_spi_clk_fre = 0.5*1000; //SPI 时钟速率,表示1M parameter p_clk_div = p_clk_fre * 1000/p_spi_clk_fre/2-1; parameter p_spi_cnt_max = p_spi_frame_width*2-1; parameter p_spi_ins_max = p_spi_ins_width*2-1; //位宽计算函数 function integer clogb2 (input integer depth); begin for (clogb2=0; depth>0; clogb2=clogb2+1) depth = depth >>1; end endfunction //把最大值赋值给线型,直接用p_clk_div仿真有问题,但实际上板是可以的 wire [clogb2(p_clk_div)-1:0] w_clk_div; assign w_clk_div = p_clk_div; ////时钟分频 reg [clogb2(p_clk_div)-1:0] r_cnt_div = ‘d0; always @(posedge i_clk) begin if (r_cnt_div == w_clk_div) r_cnt_div <= ‘d0; else r_cnt_div <= r_cnt_div + ‘d1; end //always wire w_clk_en; //分频时钟使能 assign w_clk_en = (r_cnt_div == w_clk_div) ? 1‘b1 : 1‘b0; reg [1:0] r_flag_edge = 2‘b00; reg [clogb2(p_spi_cnt_max)-1:0] r_spi_cnt = ‘d0; always @(posedge i_clk) //flag边沿检测 begin r_flag_edge <= r_flag_edge[0],i_flag; end //flag信号展宽到低速时钟域 reg r_flag_enlarge = 1‘b0; always @(posedge i_clk) begin if (r_flag_edge == 2‘b01) //上升沿拉高 r_flag_enlarge <= 1‘b1; else if (r_spi_cnt == p_spi_ins_max) //足够长的高电平才拉低 r_flag_enlarge <= 1‘b0; end reg [1:0] r_flag_enlarge_edge = 2‘b00; always @(posedge i_clk) begin if (w_clk_en) r_flag_enlarge_edge <= r_flag_enlarge_edge[0],r_flag_enlarge; end reg r_cs = 1‘b1; always @(posedge i_clk) begin if (w_clk_en) begin if (r_flag_enlarge_edge == 2‘b01) //检测到需要进行SPI操作 r_cs <= 1‘b0; else if (r_spi_cnt == p_spi_cnt_max) //计数到最大值表示一次SPI完成 r_cs <= 1‘b1; end end always @(posedge i_clk) begin if (w_clk_en) begin if(~r_cs) //在操作区间计数 r_spi_cnt <= r_spi_cnt + ‘d1; else r_spi_cnt <= ‘d0; end end ////数据传输段 reg [p_spi_frame_width-1:0] r_data = ‘d0; always @(posedge i_clk) begin if (w_clk_en) begin if (r_flag_enlarge_edge == 2‘b01) //上升沿刷入 r_data <= i_spi_data; else if (r_spi_cnt[0] == 1‘b1) //数据移动 r_data <= r_data[p_spi_frame_width-2:0],1‘b1; end end ////数据读取段 reg [p_spi_data_width-1:0] r_data_read = ‘d0; always @(posedge i_clk) begin if (w_clk_en) begin if (i_spi_data[15] && (r_spi_cnt > p_spi_ins_max) && (r_spi_cnt[0] == 1‘b0)) //是读 `ifdef SPI_LINE r_data_read <= r_data_read[p_spi_data_width-2:0],io_spi_sdio; `else r_data_read <= r_data_read[p_spi_data_width-2:0],i_spi_miso; `endif end end ////SPI输出段 assign o_spi_cs = r_cs; assign o_spi_clk = r_cs ? 1‘b0 : r_spi_cnt[0]; ////SPI SDIO的输入输出切换 `ifdef SPI_LINE assign io_spi_sdio = (i_spi_data[15]) ? (((r_spi_cnt >= ‘d0) && (r_spi_cnt <= p_spi_ins_max)) ? r_data[p_spi_frame_width-1] : 1‘bz ) : r_data[p_spi_frame_width-1]; `else assign o_spi_mosi = r_data[p_spi_frame_width-1]; `endif assign o_transfer_done = ((~r_cs) && (r_spi_cnt == p_spi_cnt_max)) ? 1‘b1:1‘b0; assign o_spi_data = r_data_read; endmodule // end the spi_master model

仿真如下所示:写入四个寄存器值,再读出。

仿真代码如下:

`define TRANSFER_NUMBER 8 //操作数为4 `define DATA 8‘ha5 //`define SPI_LINE timeunit 1ns; timeprecision 1ps; module top; parameter p_sim_end_time = 1000000; //ns logic l_clk = 1‘b0; always #2.5 l_clk = ~l_clk; ////复位 logic l_rst_n = 1‘b0; initial begin #100 l_rst_n = 1‘b1; end wire io_sdio; wire o_spi_cs; wire o_spi_clk; wire o_transfer_done; wire [7:0] o_spi_data; ////多个数据操作模式 reg r_flag = 1‘b0; reg [1:0] r_first_cnt = 2‘b00; always @(posedge l_clk,negedge l_rst_n) begin if (~l_rst_n) r_first_cnt <= 2‘b00; else if (r_first_cnt == 2‘d3) r_first_cnt <= r_first_cnt; else r_first_cnt <= r_first_cnt + 2‘d1; end reg [1:0] r_transfer_done_edge = 2‘b00; always @(posedge l_clk) begin r_transfer_done_edge <= r_transfer_done_edge[0],o_transfer_done; end reg [3:0] r_transfer_cnt = 4‘d0; always @(posedge l_clk) begin if ((r_first_cnt == 2‘d2) && (r_transfer_cnt < `TRANSFER_NUMBER)) r_flag <= 1‘b1; else if ((r_transfer_done_edge == 2‘b10) && (r_transfer_cnt < `TRANSFER_NUMBER-1)) r_flag <= 1‘b1; else r_flag <= 1‘b0; end always @(posedge l_clk) begin if (r_transfer_done_edge == 2‘b10) r_transfer_cnt <= r_transfer_cnt + ‘d1; end reg [15:0] r_in_data = 16‘d0; always @(*) begin if (~l_rst_n) //仿真不执行此段仿真会有问题 r_in_data = 16‘h0000; else begin case(r_transfer_cnt) 4‘d0:begin r_in_data = 8‘h00,8‘h43; end 4‘d1:begin r_in_data = 16‘h0132; end 4‘d2:begin r_in_data = 16‘h0245; end 4‘d3:begin r_in_data = 16‘h0367; end 4‘d4:begin r_in_data = 16‘h8000; end 4‘d5:begin r_in_data = 16‘h8100; end 4‘d6:begin r_in_data = 16‘h8200; end 4‘d7:begin r_in_data = 16‘h8300; end default:begin r_in_data = 16‘h0000; end endcase end end wire w_spi_miso; wire w_spi_mosi; spi_master inst_spi_master ( .i_clk (l_clk), .i_rst_n (), .i_flag (r_flag), .i_spi_data (r_in_data), .o_spi_cs (o_spi_cs), .o_spi_clk (o_spi_clk), `ifdef SPI_LINE .io_spi_sdio (io_sdio), `else .i_spi_miso (w_spi_miso), .o_spi_mosi (w_spi_mosi), `endif .o_transfer_done (o_transfer_done), .o_spi_data (o_spi_data) ); spi_slave inst_spi_slave ( .i_clk (l_clk), .i_rst_n (l_rst_n), .i_spi_clk (o_spi_clk), .i_spi_cs (o_spi_cs), `ifdef SPI_LINE .io_spi_sdio (io_sdio) `else .i_spi_mosi (w_spi_mosi), .o_spi_miso (w_spi_miso) `endif ); initial begin #p_sim_end_time $stop; end endmodule

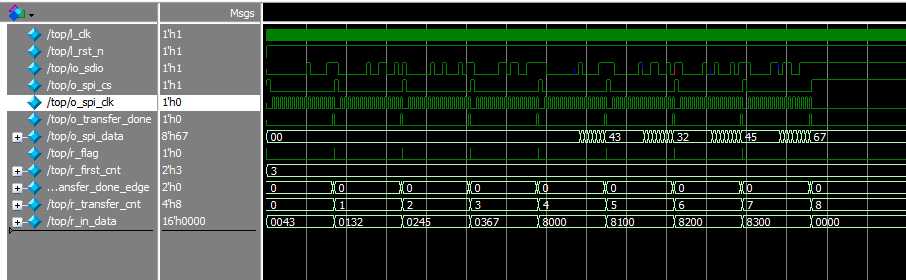

三线SPI:

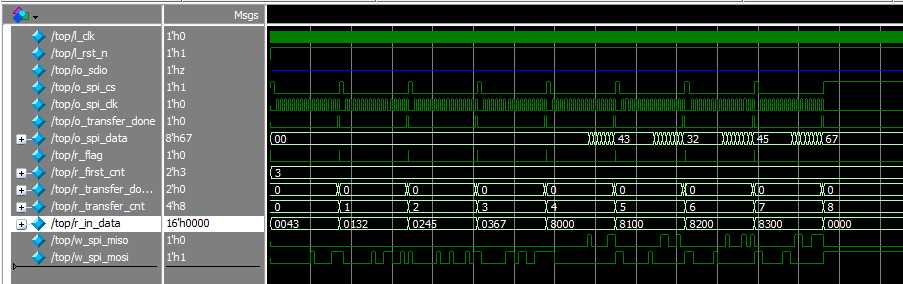

四线SPI:

可以看到读写是一致的,验证通过。

以上。

以上是关于对SPI进行参数化结构设计的主要内容,如果未能解决你的问题,请参考以下文章