机电传动控制第四周作业

Posted

tags:

篇首语:本文由小常识网(cha138.com)小编为大家整理,主要介绍了机电传动控制第四周作业相关的知识,希望对你有一定的参考价值。

结合本周学习的交流电机原理及启动、调速、制动特性,用Modelica设计和仿真一个用三相交流异步电机带动起重机起升机构运行。具体要求如下:

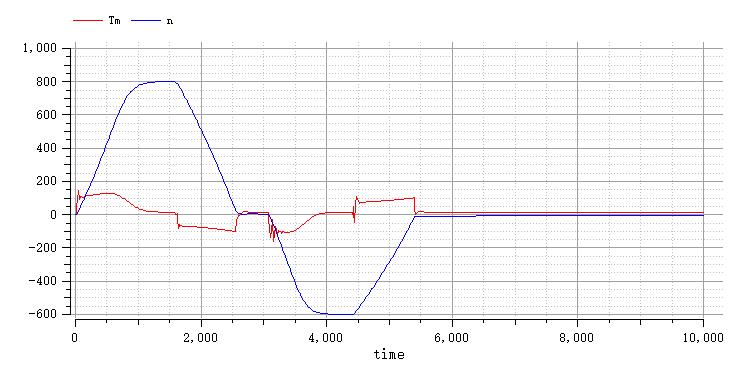

1)实现如下机械运动周期:

- 控制电机带重物上升,从静止加速到800r/min

- 保持800r/min匀速运动0.5s,

- 减速到静止,保持静止状态0.5s,

- 带重物下降,从静止达到600r/min

- 保持600r/min匀速运动0.6s,

- 减速到静止。

(为了便于仿真,匀速和静止持续时间较短)

2) 升降机构和重物折算到到电机转子轴上的等效负载惯量为1Kg.m^2,折算到到电机转子轴上的等效负载转矩是15N.m。

3)使用统一的电机模型,如果控制策略中用到转子串电阻,允许将该电机的转子改为绕线式转子(参数不变)。

4)参照教材中给出的交流电机启动、调速和制动方法,设计控制策略,用Modelica实现控制策略并与电机模型实现联合仿真。

5)可以采用定子串电阻、转子串电阻、定子调压、定子调频等手段,但必须具备工程上的可实施性。

6)评价指标:快速启动、制动,冲击转矩和冲击电流小,能耗小,兼顾实施的经济性。

设计分析:

由实际情况分析可知,为了达到要求的起动转矩的同时尽量减小启动电流,采用了自耦变压器降压启动,为了能耗小无级调速并有较大的调速范围使用变频调速,最后采用反接制动的方式对交流电机的上述过程进行分析和仿真。

代码:

model SACIM "A Simple AC Induction Motor Model"

type Voltage=Real(unit="V");

type Current=Real(unit="A");

type Resistance=Real(unit="Ohm");

type Inductance=Real(unit="H");

type Speed=Real(unit="r/min");

type Torque=Real(unit="N.m");

type Inertia=Real(unit="kg.m^2");

type Frequency=Real(unit="Hz");

type Flux=Real(unit="Wb");

type Angle=Real(unit="rad");

type AngularVelocity=Real(unit="rad/s");

constant Real Pi = 3.1415926;

Current i_A"A Phase Current of Stator";

Current i_B"B Phase Current of Stator";

Current i_C"C Phase Current of Stator";

Voltage u_A"A Phase Voltage of Stator";

Voltage u_B"B Phase Voltage of Stator";

Voltage u_C"C Phase Voltage of Stator";

Current i_a"A Phase Current of Rotor";

Current i_b"B Phase Current of Rotor";

Current i_c"C Phase Current of Rotor";

Frequency f_s"Frequency of Stator";

Torque Tm"Torque of the Motor";

Speed n"Speed of the Motor";

Resistance Rs"Stator Resistance";

Torque Tl"Load Torque";

Flux Psi_A"A Phase Flux-Linkage of Stator";

Flux Psi_B"B Phase Flux-Linkage of Stator";

Flux Psi_C"C Phase Flux-Linkage of Stator";

Flux Psi_a"a Phase Flux-Linkage of Rotor";

Flux Psi_b"b Phase Flux-Linkage of Rotor";

Flux Psi_c"c Phase Flux-Linkage of Rotor";

Angle phi"Electrical Angle of Rotor";

Angle phi_m"Mechnical Angle of Rotor";

AngularVelocity w"Angular Velocity of Rotor";

parameter Resistance Rr=0.408"Rotor Resistance";

parameter Inductance Ls = 0.00252"Stator Leakage Inductance";

parameter Inductance Lr = 0.00252"Rotor Leakage Inductance";

parameter Inductance Lm = 0.00847"Mutual Inductance";

parameter Frequency f_N = 50"Rated Frequency of Stator";

parameter Voltage u_N = 220"Rated Phase Voltage of Stator";

parameter Real p =2"number of pole pairs";

parameter Inertia Jm = 0.1"Motor Inertia";

parameter Inertia Jl = 1"Load Inertia";

parameter Real K=0.8"starting rate";

parameter Real a=0.544"frequency rate";

parameter Real b=0.0683"stable frequency rate";

parameter Real c=0.3893"another frequency rate";

parameter Real P=0.7"stoping rate";

initial equation

Psi_A = 0;

Psi_B = 0;

Psi_C = 0;

Psi_a = 0;

Psi_b = 0;

Psi_c = 0;

phi = 0;

w = 0;

equation

u_A = Rs * i_A + 1000 * der(Psi_A);

u_B = Rs * i_B + 1000 * der(Psi_B);

u_C = Rs * i_C + 1000 * der(Psi_C);

0 = Rr * i_a + 1000 * der(Psi_a);

0 = Rr * i_b + 1000 * der(Psi_b);

0 = Rr * i_c + 1000 * der(Psi_c);

Psi_A =(Lm+Ls)*i_A+(-0.5*Lm)*i_B+(-0.5*Lm)*i_C+(Lm*cos(phi))*i_a+(Lm*cos(phi+2*Pi/3))*i_b+(Lm*cos(phi-2*Pi/3))*i_c;

Psi_B =(-0.5*Lm)*i_A+(Lm+Ls)*i_B+(-0.5*Lm)*i_C+(Lm*cos(phi-2*Pi/3))*i_a+(Lm*cos(phi))*i_b+(Lm*cos(phi+2*Pi/3))*i_c;

Psi_C =(-0.5*Lm)*i_A+(-0.5*Lm)*i_B+(Lm+Ls)*i_C+(Lm*cos(phi+2*Pi/3))*i_a+(Lm*cos(phi-2*Pi/3))*i_b+(Lm*cos(phi))*i_c;

Psi_a =(Lm*cos(phi))*i_A+(Lm*cos(phi-2*Pi/3))*i_B + (Lm*cos(phi+2*Pi/3))*i_C + (Lm+Lr)*i_a + (-0.5*Lm)*i_b + (-0.5*Lm)*i_c;

Psi_b =(Lm*cos(phi+2*Pi/3))*i_A+(Lm*cos(phi))*i_B + (Lm*cos(phi-2*Pi/3))*i_C + (-0.5*Lm)*i_a + (Lm+Lr)*i_b + (-0.5*Lm)*i_c;

Psi_c =(Lm*cos(phi-2*Pi/3))*i_A + (Lm*cos(phi+2*Pi/3))*i_B + (Lm*cos(phi))*i_C + (-0.5*Lm)*i_a + (-0.5*Lm)*i_b + (Lm+Lr)*i_c;

Tm =-p*Lm*((i_A*i_a+i_B*i_b+i_C*i_c)*sin(phi)+(i_A*i_b+i_B*i_c+i_C*i_a)*sin(phi+2*Pi/3)+(i_A*i_c+i_B*i_a+i_C*i_b)*sin(phi-2*Pi/3));

w = 1000 * der(phi_m);

phi_m = phi/p;

n= w*60/(2*Pi);

Tm-Tl = (Jm+Jl) * 1000 * der(w);

Tl = 15;

if time <= 100 then

u_A = 0;

u_B = 0;

u_C = 0;

f_s = 0;Rs = 0.531;

elseif time<=120 then

f_s = f_N*a; Rs = 0.531;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*K*a;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*K*a;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*K*a;

elseif time<=1810 then

f_s = f_N*a;Rs = 0.531;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*a;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*a;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*a;

elseif time<=1920 then

f_s = f_N*a;Rs = 3;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*a;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*a;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*a;

elseif time<=2767 then

f_s = f_N*a;Rs = 0.531;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*a;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*a;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*a;

elseif time<=3250 then

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*b;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*b;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*b;

f_s = f_N*b;Rs = 0.531;

elseif time<=3600 then

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*K*c;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*K*c;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*K*c;

f_s = f_N*K*c;Rs = 0.531;

elseif time<=4879 then

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*c;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*c;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*c;

f_s = f_N*c;Rs = 0.531;

elseif time<=4980 then

f_s = f_N*P*a;Rs = 2;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*a*P;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*a*P;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*a*P;

elseif time<=5660 then

f_s = f_N*a;Rs = 0.531;

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*a;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*a;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*a;

else

u_A = u_N * 1.414 * sin(2*Pi*f_s*time/1000)*b;

u_B = u_N * 1.414 * sin(2*Pi*f_s*time/1000-2*Pi/3)*b;

u_C = u_N * 1.414 * sin(2*Pi*f_s*time/1000-4*Pi/3)*b;

f_s = f_N*b;Rs = 0.531;

end if;

end SACIM;

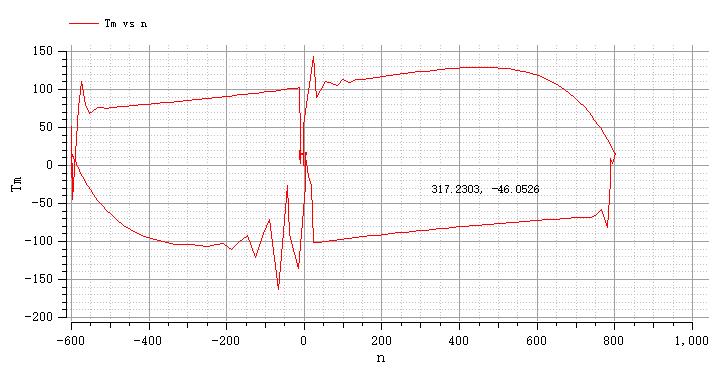

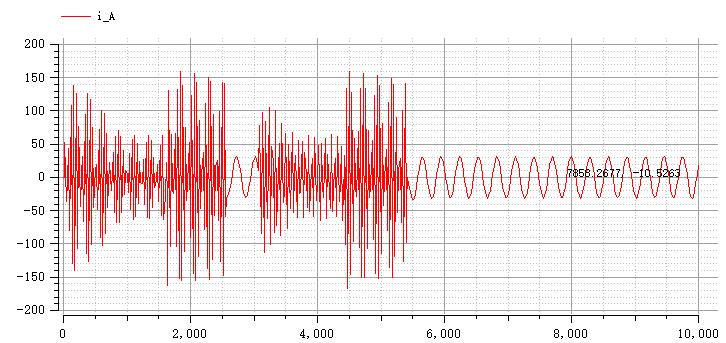

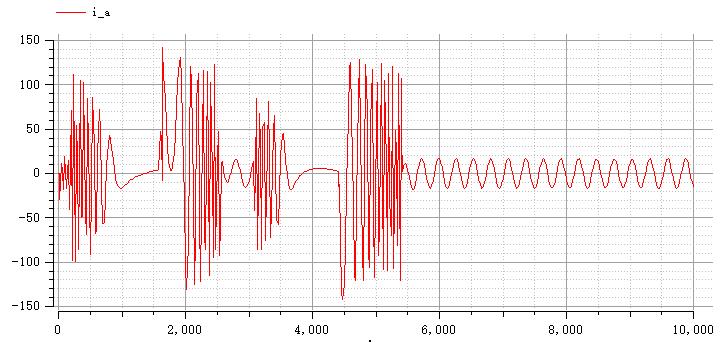

整个过程需要5400~5500ms ,电机转矩最大值不超过180N.m 电流峰值比较高。

以上是关于机电传动控制第四周作业的主要内容,如果未能解决你的问题,请参考以下文章