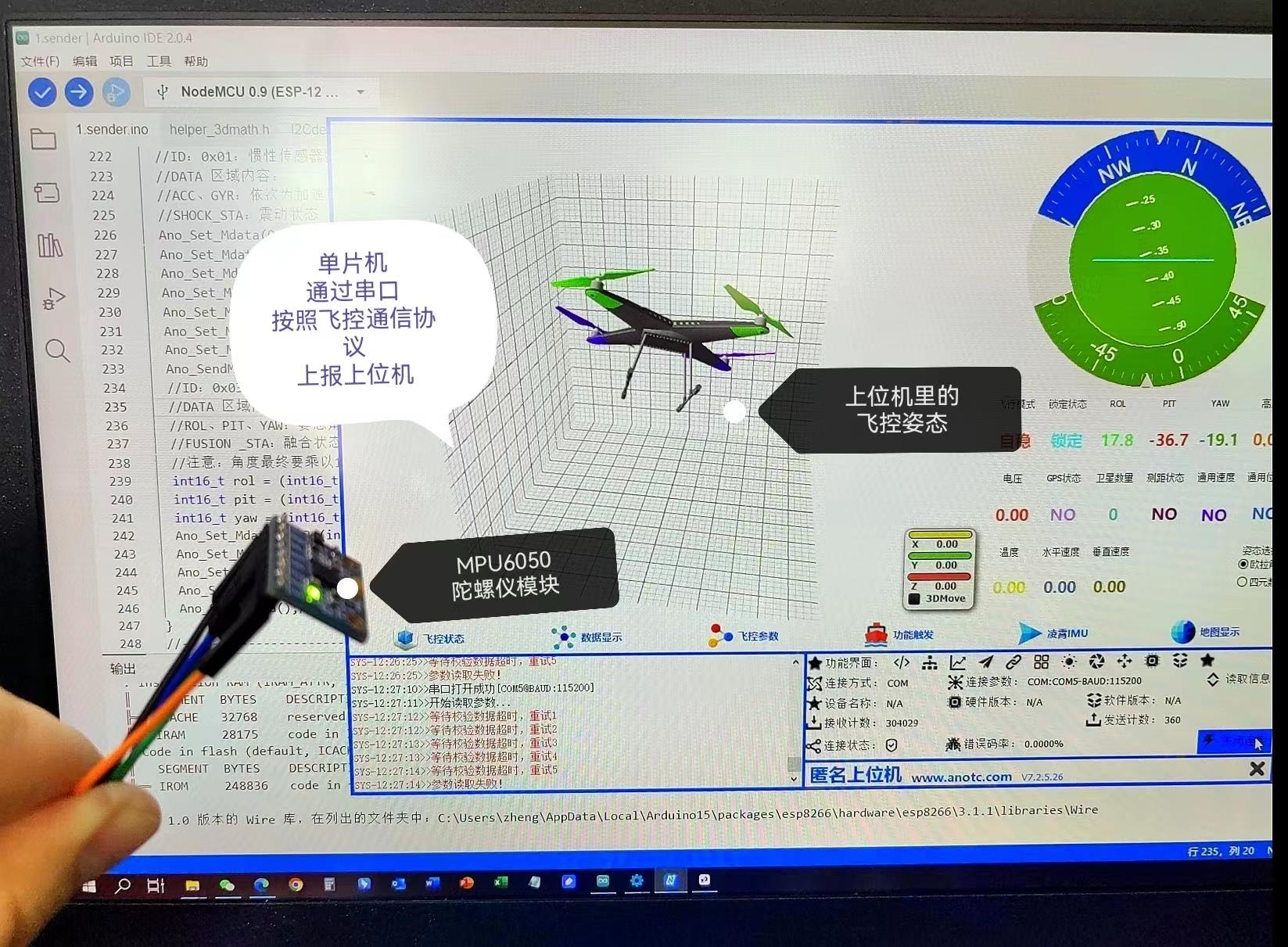

MPU6050陀螺仪与Processing和上位机飞控联动实录

Posted 旁观者-郑昀

tags:

篇首语:本文由小常识网(cha138.com)小编为大家整理,主要介绍了MPU6050陀螺仪与Processing和上位机飞控联动实录相关的知识,希望对你有一定的参考价值。

一,MPU6050简介

二,MUP6050特点

三,原理说明

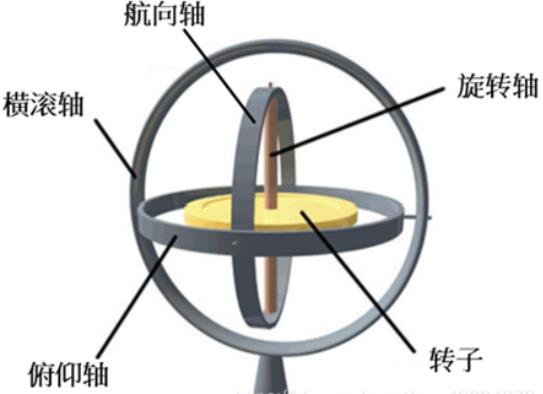

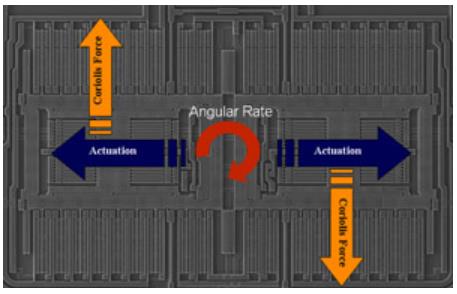

3.1.MEMS陀螺仪

3.2.MEMS加速度计

四,模块初始化工作

4.1.初始化 IIC 接口

4.2.复位 MPU6050

const uint8_t MPU6050_REGISTER_PWR_MGMT_1 = 0x6B;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_1, 0x01);4.3.设置角速度传感器(陀螺仪)和加速度传感器的满量程范围

4.4.设置其他参数

- 关闭中断

- 关闭 AUX IIC 接口

- 禁止 FIFO

- 设置陀螺仪采样率

- 设置数字低通滤波器(DLPF)等。

const uint8_t MPU6050_REGISTER_INT_ENABLE = 0x38;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_INT_ENABLE, 0x01);

const uint8_t MPU6050_REGISTER_USER_CTRL = 0x6A;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_USER_CTRL, 0x00);const uint8_t MPU6050_REGISTER_FIFO_EN = 0x23;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_FIFO_EN, 0x00);const uint8_t MPU6050_REGISTER_SMPLRT_DIV = 0x19;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SMPLRT_DIV, 0x07);const uint8_t MPU6050_REGISTER_CONFIG = 0x1A;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_CONFIG, 0x00);4.5.配置系统时钟源并使能角速度传感器和加速度传感器

const uint8_t MPU6050_REGISTER_PWR_MGMT_2 = 0x6C;

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_2, 0x00);五,数据处理

5.1.原始数据格式

5.2.DMP处理成欧拉角

q0=quat[0] / q30;//q30格式转换为浮点数

q1=quat[1] / q30;

q2=quat[2] / q30;

q3=quat[3] / q30; //计算得到ypr:pitch俯仰角/roll横滚角/yaw航向角

pitch=asin(-2 * q1 * q3 + 2 * q0* q2)* 57.3;//俯仰角

roll=atan2(2 * q2 * q3 + 2 * q0 * q1, -2 * q1 * q1 - 2 * q2* q2 + 1)* 57.3;//横滚角

yaw=atan2(2*(q1q2 + q0q3),q0q0+q1q1-q2q2-q3q3) * 57.3;//航向角5.3.Yaw角的问题

5.4.数据校准和滤波

float valSums[7] = 0.0f, 0.0f, 0.0f, 0.0f, 0.0f, 0.0f, 0.0;

//先求和

for (int i = 0; i < nCalibTimes; ++i)

int mpuVals[nValCnt];

ReadAccGyr(mpuVals);

for (int j = 0; j < nValCnt; ++j)

valSums[j] += mpuVals[j];

//再求平均

for (int i = 0; i < nValCnt; ++i)

calibData[i] = int(valSums[i] / nCalibTimes);

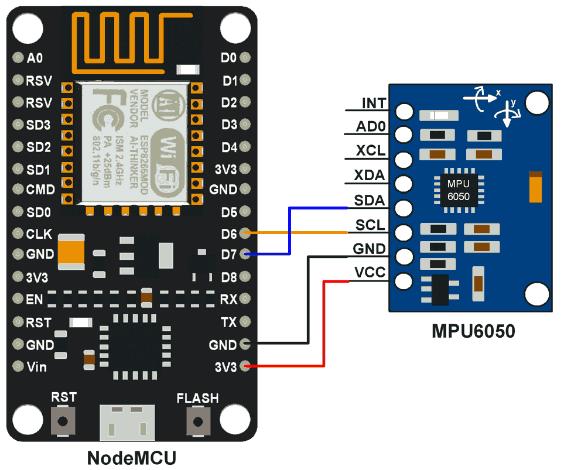

calibData[2] += 16384;六、接线方式

#include <Wire.h>

// MPU6050 Slave Device Address

const uint8_t MPU6050SlaveAddress = 0x68;//MPU6050的I2C地址

// Select SDA and SCL pins for I2C communication

const uint8_t scl = D6;

const uint8_t sda = D7;

// sensitivity scale factor respective to full scale setting provided in datasheet

const uint16_t AccelScaleFactor = 16384;

const uint16_t GyroScaleFactor = 131;

// MPU6050 few configuration register addresses

const uint8_t MPU6050_REGISTER_SMPLRT_DIV = 0x19;

const uint8_t MPU6050_REGISTER_USER_CTRL = 0x6A;

const uint8_t MPU6050_REGISTER_PWR_MGMT_1 = 0x6B;

const uint8_t MPU6050_REGISTER_PWR_MGMT_2 = 0x6C;

const uint8_t MPU6050_REGISTER_CONFIG = 0x1A;

const uint8_t MPU6050_REGISTER_GYRO_CONFIG = 0x1B;

const uint8_t MPU6050_REGISTER_ACCEL_CONFIG = 0x1C;

const uint8_t MPU6050_REGISTER_FIFO_EN = 0x23;

const uint8_t MPU6050_REGISTER_INT_ENABLE = 0x38;

const uint8_t MPU6050_REGISTER_ACCEL_XOUT_H = 0x3B;//我们感兴趣的数据位于 0X3B 到 0X48 这14个字节的寄存器当中

const uint8_t MPU6050_REGISTER_SIGNAL_PATH_RESET = 0x68;

int16_t AccelX, AccelY, AccelZ, Temperature, GyroX, GyroY, GyroZ;

void setup()

Serial.begin(115200);

Wire.begin(sda, scl);

MPU6050_Init();

void loop()

double Ax, Ay, Az, T, Gx, Gy, Gz;

Read_RawValue(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_XOUT_H);

//divide each with their sensitivity scale factor

Ax = (double)AccelX/AccelScaleFactor;

Ay = (double)AccelY/AccelScaleFactor;

Az = (double)AccelZ/AccelScaleFactor;

T = (double)Temperature/340+36.53; //temperature formula

Gx = (double)GyroX/GyroScaleFactor;

Gy = (double)GyroY/GyroScaleFactor;

Gz = (double)GyroZ/GyroScaleFactor;

Serial.print("Ax: "); Serial.print(Ax);

Serial.print(";Ay: "); Serial.print(Ay);

Serial.print(";Az: "); Serial.print(Az);

Serial.print(";T: "); Serial.print(T);

Serial.print(";Gx: "); Serial.print(Gx);

Serial.print(";Gy: "); Serial.print(Gy);

Serial.print(";Gz: "); Serial.println(Gz);

delay(100);

void I2C_Write(uint8_t deviceAddress, uint8_t regAddress, uint8_t data)

Wire.beginTransmission(deviceAddress);

Wire.write(regAddress);

Wire.write(data);

Wire.endTransmission();

// read all 14 register

void Read_RawValue(uint8_t deviceAddress, uint8_t regAddress)

Wire.beginTransmission(deviceAddress);

Wire.write(regAddress);

Wire.endTransmission();

Wire.requestFrom(deviceAddress, (uint8_t)14);

AccelX = (((int16_t)Wire.read()<<8) | Wire.read());

AccelY = (((int16_t)Wire.read()<<8) | Wire.read());

AccelZ = (((int16_t)Wire.read()<<8) | Wire.read());

Temperature = (((int16_t)Wire.read()<<8) | Wire.read());

GyroX = (((int16_t)Wire.read()<<8) | Wire.read());

GyroY = (((int16_t)Wire.read()<<8) | Wire.read());

GyroZ = (((int16_t)Wire.read()<<8) | Wire.read());

//configure MPU6050

void MPU6050_Init()

delay(150);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SMPLRT_DIV, 0x07);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_1, 0x01);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_2, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_CONFIG, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_GYRO_CONFIG, 0x00);//set +/-250 degree/second full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_CONFIG, 0x00);// set +/- 2g full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_FIFO_EN, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_INT_ENABLE, 0x01);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SIGNAL_PATH_RESET, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_USER_CTRL, 0x00);

七,外接Processing实验

#define OUTPUT_READABLE_YAWPITCHROLL#define OUTPUT_TEAPOT

attachInterrupt(digitalPinToInterrupt(INTERRUPT_PIN), dmpDataReady, RISING);

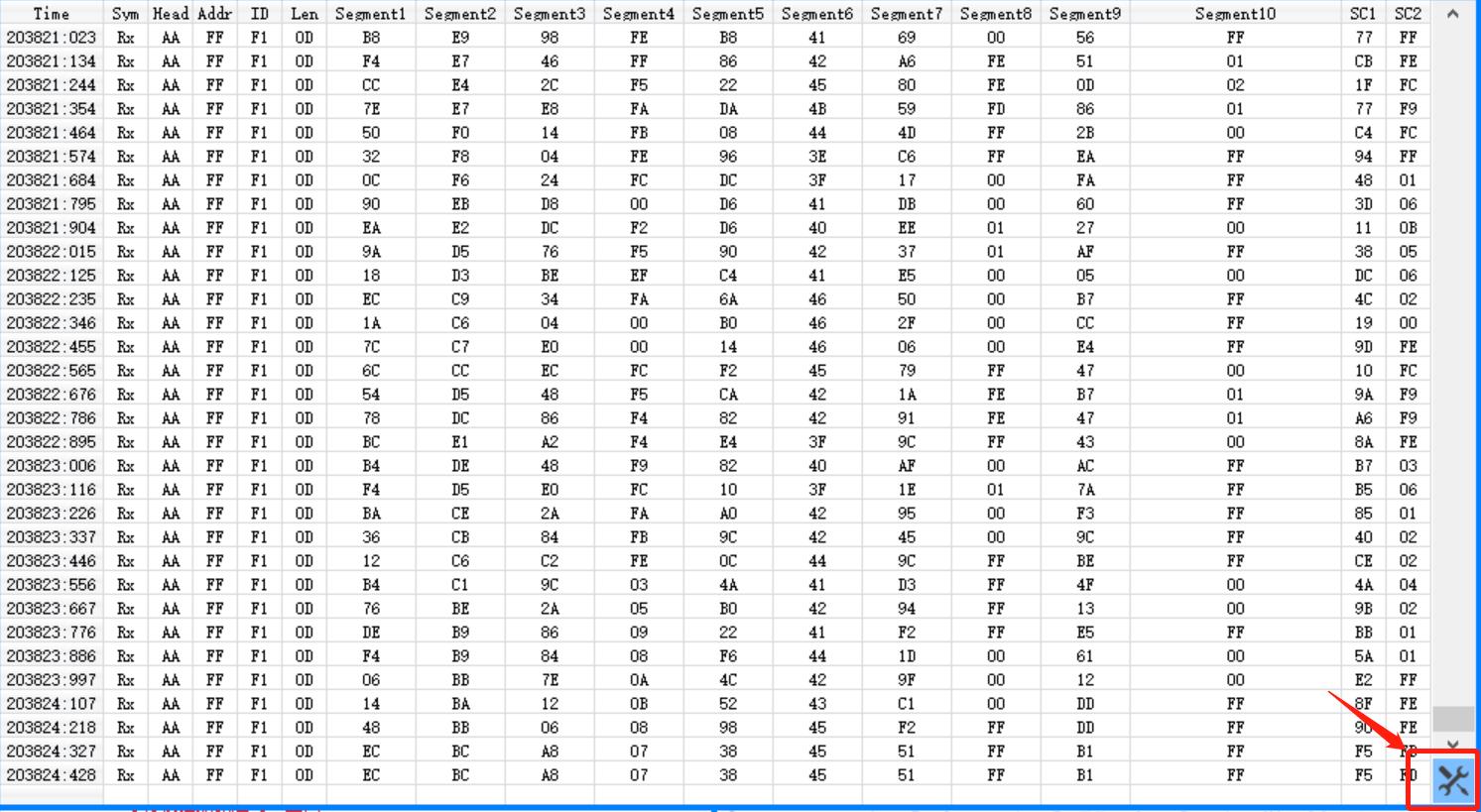

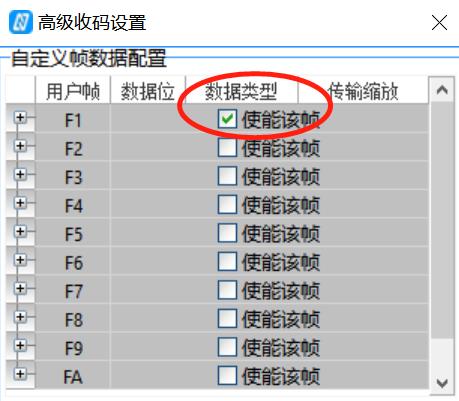

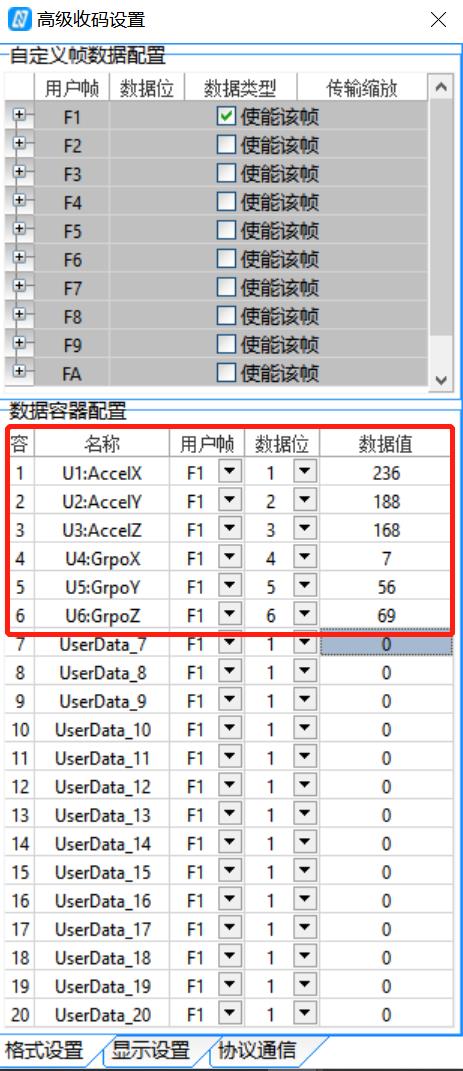

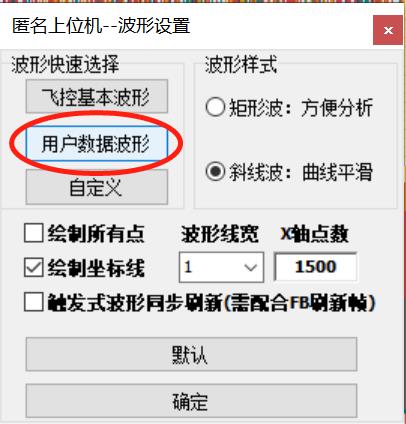

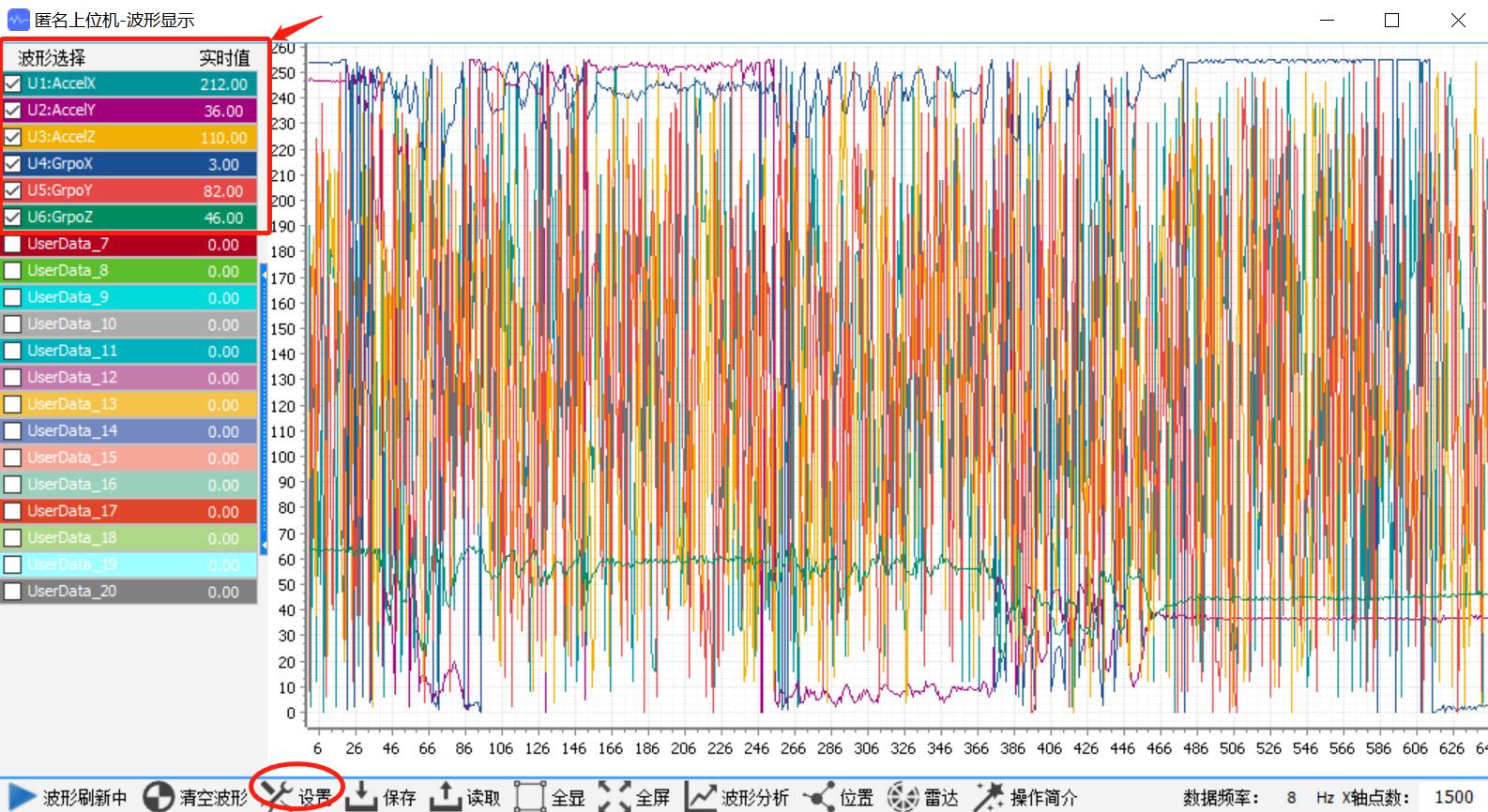

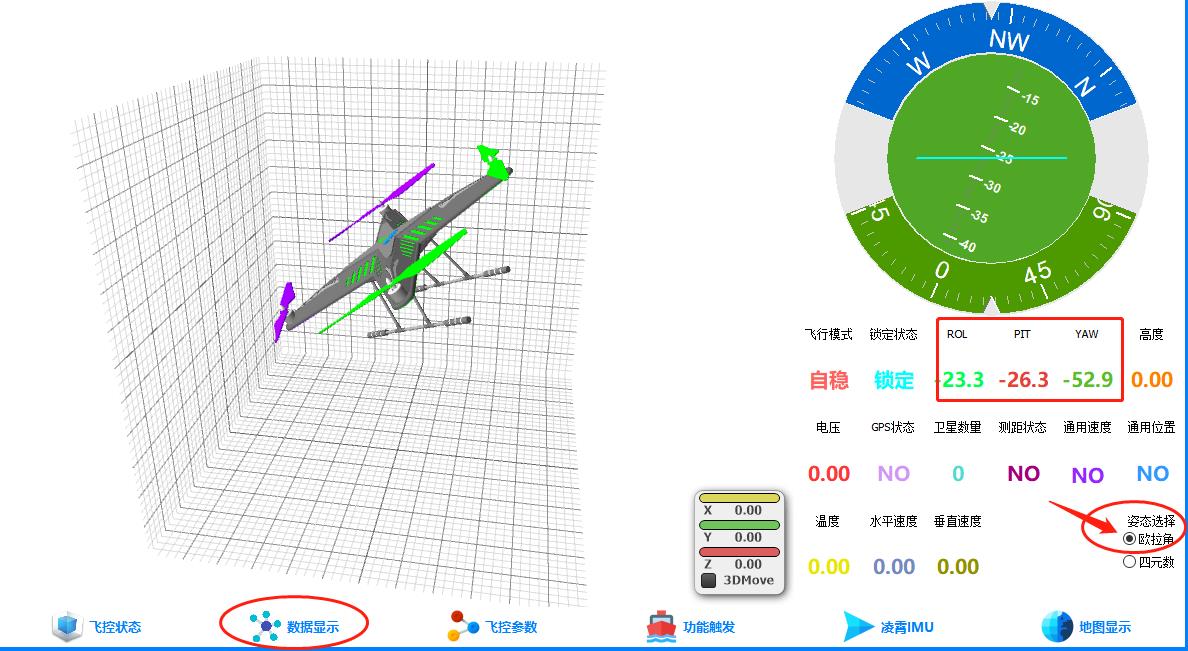

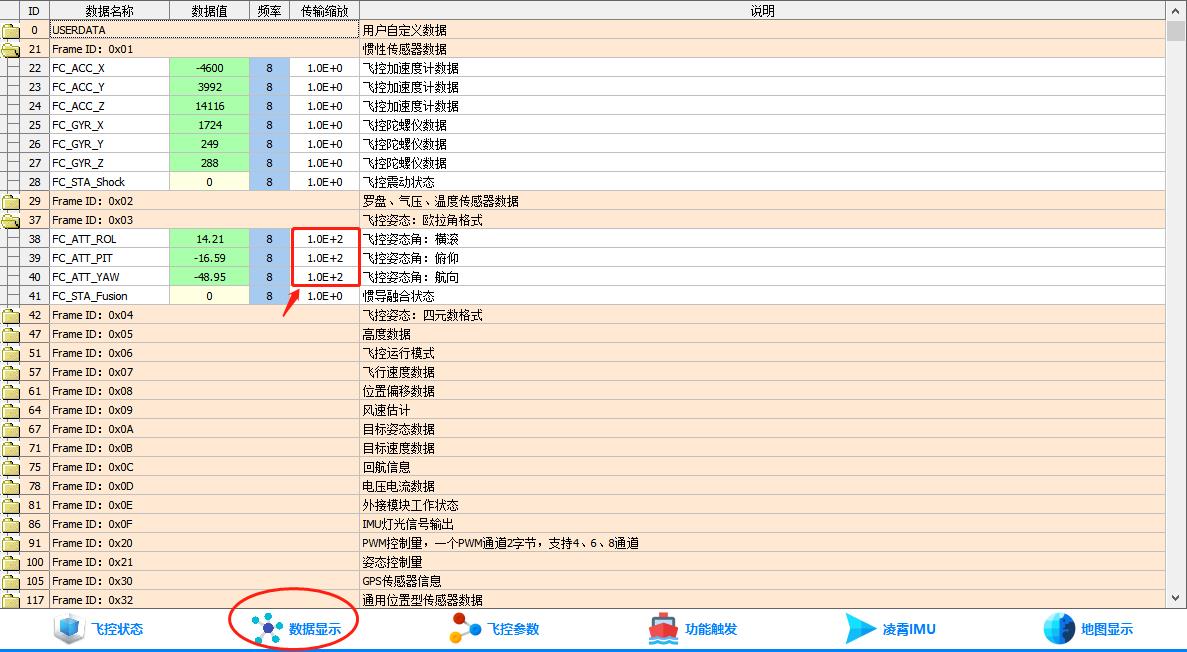

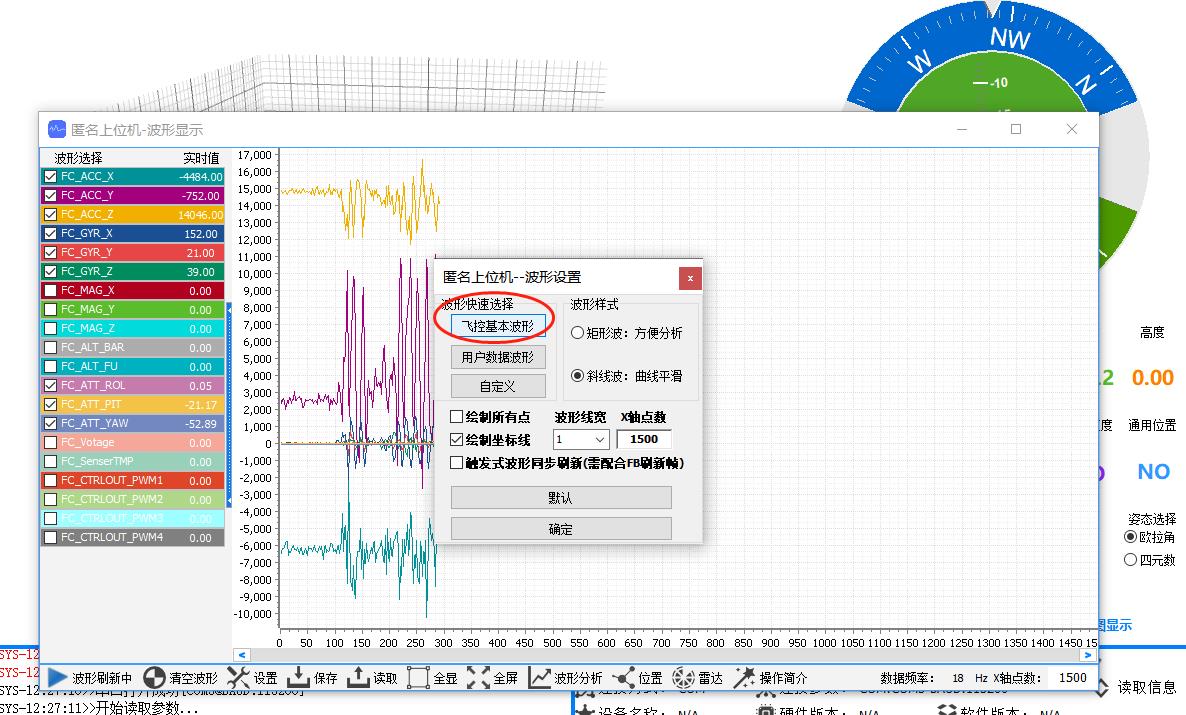

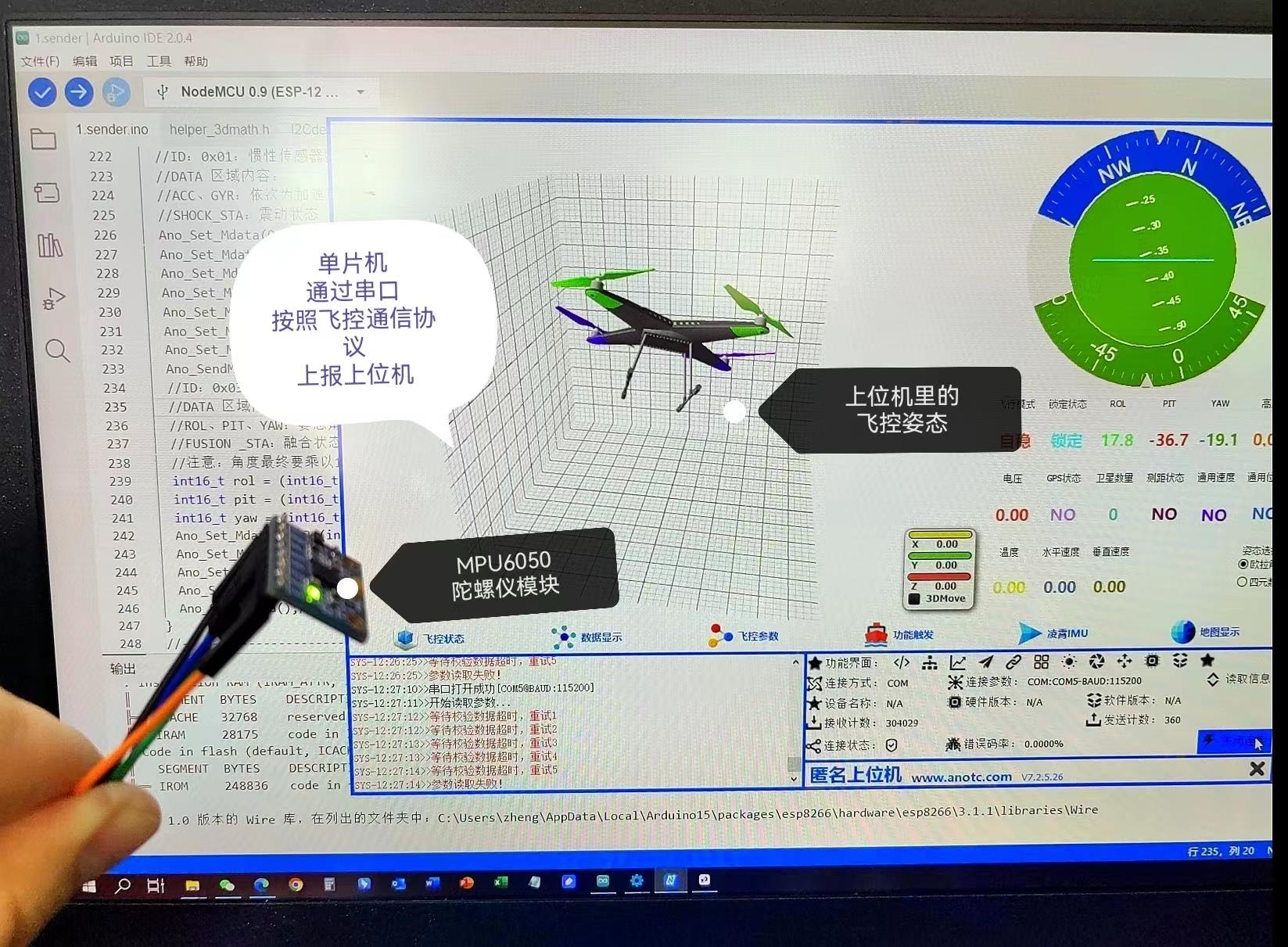

mpuIntStatus = mpu.getIntStatus();八,外接匿名上位机(V7)

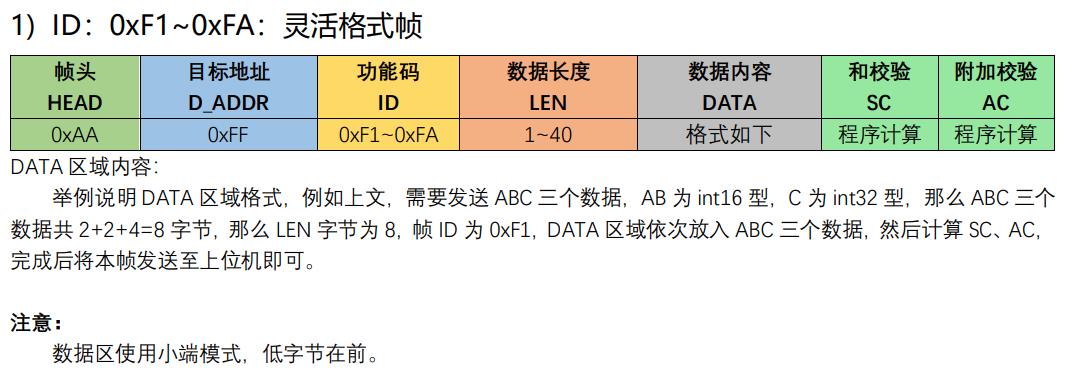

8.1.单片机上报灵活格式帧给上位机

void Ano_Init(void)

MyAno.Head = FRAME_HEADER;//0XAA是帧头

MyAno.Addr = GENERAL_OUTPUT_ADDR;//地址码为0xFF,指的是无特定目标,用于数据广播型输出

MyAno.Lenth = 0;

//-----------------与匿名上位机通讯-----------------------------

/** 发送灵活格式帧,帧ID为0xF1~0xFA

* 功能:发送加速度传感器和陀螺仪传感器数据给匿名上位机(V7)

* 入口参数:第一个参数accel,它的三个元素是xyz三个方向的加速度值

* 第二个参数gyro,它的三个元素是xyz三个方向的陀螺仪值

* 返回值:无

* 注:数据格式:帧头0xAA+目标地址0xFF+功能码0xF1+数据长度LEN+DATA+和校验SC+附加校验AC

*/

void mpu6050_send_data2ano(VectorInt16 *accel,VectorInt16 *gyro)

uint8_t nul = 0;

Ano_Set_Mdata(0xF1,(int16_t*)&accel->x,sizeof(accel->x),1);

Ano_Set_Mdata(0xF1,(int16_t*)&accel->y,sizeof(accel->y),2);

Ano_Set_Mdata(0xF1,(int16_t*)&accel->z,sizeof(accel->z),3);

Ano_Set_Mdata(0xF1,(int16_t*)&gyro->x,sizeof(gyro->x),4);

Ano_Set_Mdata(0xF1,(int16_t*)&gyro->y,sizeof(gyro->y),5);

Ano_Set_Mdata(0xF1,(int16_t*)&gyro->z,sizeof(gyro->z),6);

Ano_Set_Mdata(0xF1,(uint8_t*)&nul,sizeof(nul),7);//加载数据到对应的数据位

Ano_SendMdata();//发送数据

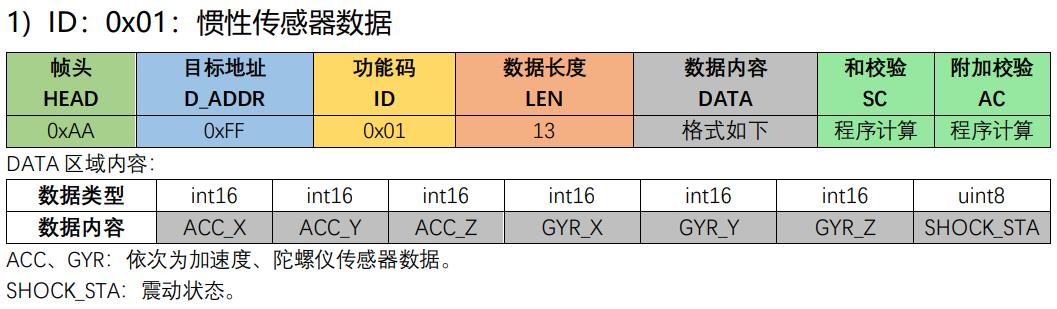

8.2.单片机上报飞行状态数据给上位机

//-----------------与匿名上位机通讯-----------------------------

/** 发送基本信息类帧,功能码ID为0x01~0x04之间,在飞控通信协议里属于飞控相关信息类

* 功能:发送惯性传感器、欧拉角等数据给匿名上位机(V7)

* 入口参数:第一个参数accel,它的三个元素是xyz三个方向的加速度值

* 第二个参数gyro,它的三个元素是xyz三个方向的陀螺仪值

* 第三个参数ypr,这是一个float[]数组,分别是yaw/pitch/roll angles原始值

* 返回值:无

* 注:数据格式:帧头0xAA+目标地址0xFF+功能码+数据长度LEN+DATA+和校验SC+附加校验AC

* 注:为了提高数据传输的效率,当有浮点数类型数据需要传输时,根据数据类型的特点,适当截取小数点后固定几

位,比如飞控姿态数据,保留角度的小数点后两位即可(即乘以100)。

将浮点数转化成整数类型进行传输,可缩短数据长度,并且避免浮点数传输时发生异

常,解析成非法浮点数。

*/

void mpu6050_send_flydata2ano(VectorInt16 *accel,VectorInt16 *gyro,float *ypr)

uint8_t nul = 0;

//ID:0x01:惯性传感器数据

//DATA 区域内容:

//ACC、GYR:依次为加速度、陀螺仪传感器数据。

//SHOCK_STA:震动状态

Ano_Set_Mdata(0x01,(int16_t*)&accel->x,sizeof(accel->x),1);

Ano_Set_Mdata(0x01,(int16_t*)&accel->y,sizeof(accel->y),2);

Ano_Set_Mdata(0x01,(int16_t*)&accel->z,sizeof(accel->z),3);

Ano_Set_Mdata(0x01,(int16_t*)&gyro->x,sizeof(gyro->x),4);

Ano_Set_Mdata(0x01,(int16_t*)&gyro->y,sizeof(gyro->y),5);

Ano_Set_Mdata(0x01,(int16_t*)&gyro->z,sizeof(gyro->z),6);

Ano_Set_Mdata(0x01,(uint8_t*)&nul,sizeof(nul),7);

Ano_SendMdata();//发送数据

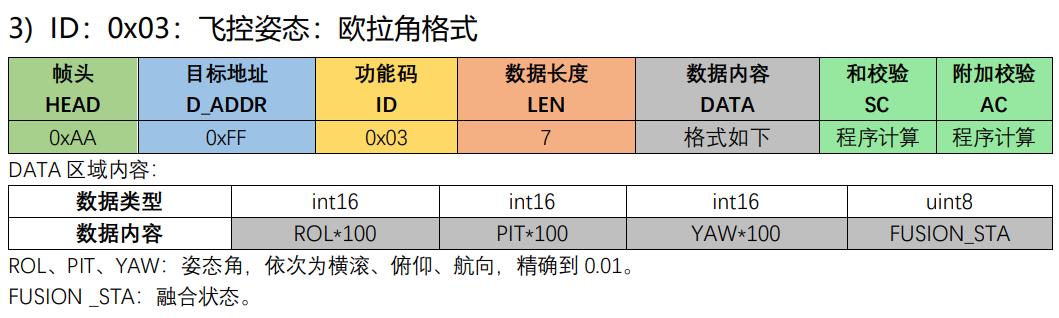

//ID:0x03:飞控姿态:欧拉角格式

//DATA 区域内容:

//ROL、PIT、YAW:姿态角,依次为横滚、俯仰、航向,精确到 0.01。

//FUSION _STA:融合状态

//注意:角度最终要乘以100,上位机那边会除以100做展示

int16_t rol = (int16_t)(ypr[2] * 180 * 100.00 / M_PI);

int16_t pit = (int16_t)(ypr[1] * 180 * 100.00 / M_PI);

int16_t yaw = (int16_t)(ypr[0] * 180 * 100.00 / M_PI);

Ano_Set_Mdata(0x03,(int16_t*)&rol,sizeof(rol),1);

Ano_Set_Mdata(0x03,(int16_t*)&pit,sizeof(pit),2);

Ano_Set_Mdata(0x03,(int16_t*)&yaw,sizeof(yaw),3);

Ano_Set_Mdata(0x03,(uint8_t*)&nul,sizeof(nul),4);

Ano_SendMdata();//发送数据

ESP32上手笔记 | 05 - 获取MPU6050数据进行姿态解算和展示(I2Cdev+MPU6050+Processing)

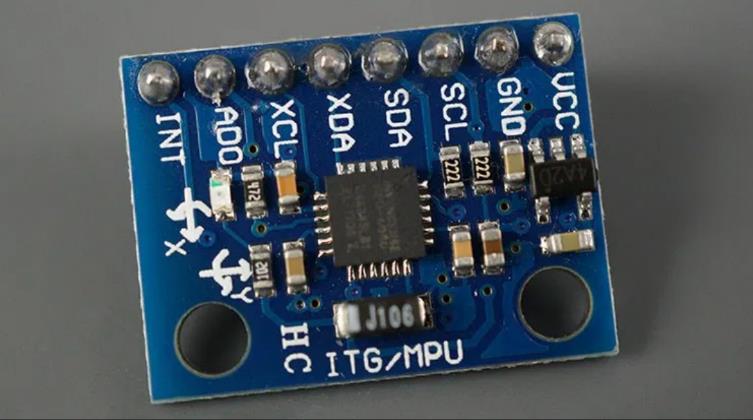

一、MPU6050陀螺仪加速度计传感器

1. 介绍

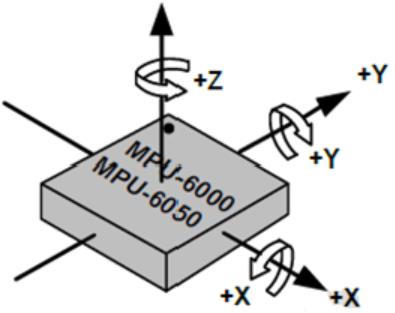

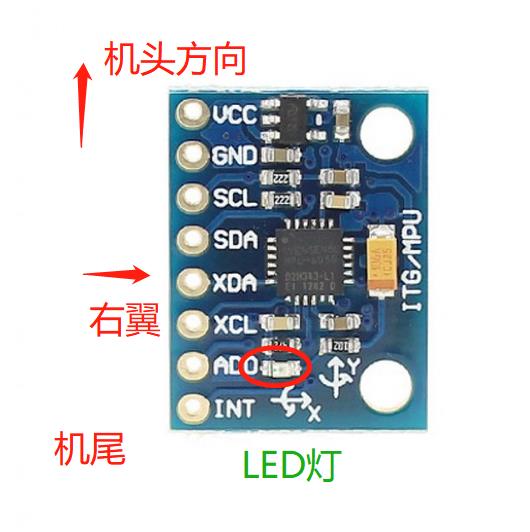

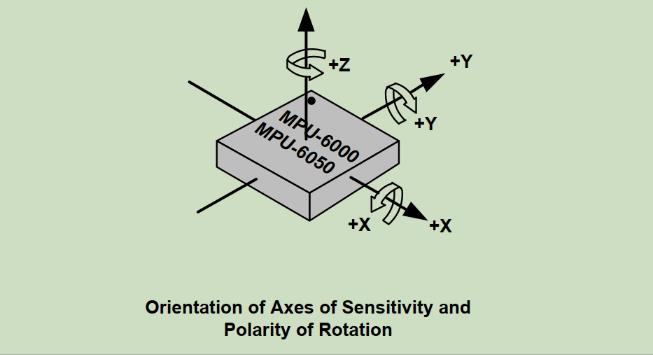

MPU6050是一个带有3轴加速度计和3轴陀螺仪的传感器,也称之为惯性测量单元(IMU)传感器:

陀螺仪测量回转的速度(rad/s),是在X、Y、Z三个轴的角位置变化,分别称为roll、pitch、yaw,这可以使我们判断物体的朝向:

加速度计用来测量加速度,也就是物体速度的变化率。

2. 模块引脚说明

- VCC:3.3V

- GND

- SCL:用于I2C通信

- SDA:用于I2C通信

- XDA:用来连接其它的I2C传感器到MPU6050

- XCL:用来连接其它的I2C传感器到MPU6050

- AD0:用来设置I2C从机地址

- INT:中断引脚,用来表示有新的测量数据可用

3. I2C通信协议

MPU6050的I2C从机地址是110100X,7bit长度,最低位X由AD0引脚来控制。

MPU6050支持的最大I2C速度为400kHz。

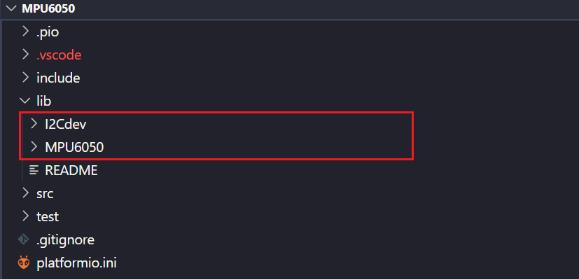

二、i2cdevlib

I2C Device Library(i2cdevlib)是一组基本统一且文档良好的类的集合,为I2C设备提供简单直观的接口。

1. 安装库

Github仓库地址:https://github.com/jrowberg/i2cdevlib

拉取到之后,将其中Arduino下的I2Cdev文件夹和MPU6050文件夹复制到platformIO工程的lib路径中。

2. 使用库

包含头文件:

#include "I2Cdev.h"

#include "MPU6050.h"

2.1. 创建MPU6050对象

MPU6050_Base(uint8_t address=MPU6050_DEFAULT_ADDRESS, void *wireObj=0);

构造函数中address参数是指MPU6050的从机地址,

默认是0x68(AD0引脚为低电平),如果AD0引脚接为高电平,可以指定地址为0x69。

2.2. 初始化

/** Power on and prepare for general usage.

* This will activate the device and take it out of sleep mode (which must be done

* after start-up). This function also sets both the accelerometer and the gyroscope

* to their most sensitive settings, namely +/- 2g and +/- 250 degrees/sec, and sets

* the clock source to use the X Gyro for reference, which is slightly better than

* the default internal clock source.

*/

void MPU6050_Base::initialize();

2.3. 测试通信是否正常

/** Verify the I2C connection.

* Make sure the device is connected and responds as expected.

* @return True if connection is valid, false otherwise

*/

bool MPU6050_Base::testConnection()

return getDeviceID() == 0x34;

2.4. 获取六轴数据

/** Get raw 6-axis motion sensor readings (accel/gyro).

* Retrieves all currently available motion sensor values.

* @param ax 16-bit signed integer container for accelerometer X-axis value

* @param ay 16-bit signed integer container for accelerometer Y-axis value

* @param az 16-bit signed integer container for accelerometer Z-axis value

* @param gx 16-bit signed integer container for gyroscope X-axis value

* @param gy 16-bit signed integer container for gyroscope Y-axis value

* @param gz 16-bit signed integer container for gyroscope Z-axis value

* @see getAcceleration()

* @see getRotation()

* @see MPU6050_RA_ACCEL_XOUT_H

*/

void MPU6050_Base::getMotion6(int16_t* ax, int16_t* ay, int16_t* az, int16_t* gx, int16_t* gy, int16_t* gz);

三、获取MPU6050原始数据

1. 硬件连接

2. 代码编写

#include <Arduino.h>

#include "I2Cdev.h"

#include "MPU6050.h"

#include "Wire.h"

class IMU

private:

MPU6050 imu;

int16_t ax, ay, az;

int16_t gx, gy, gz;

int16_t temperature;

public:

int init();

void update();

int16_t getAccelX();

int16_t getAccelY();

int16_t getAccelZ();

int16_t getGyroX();

int16_t getGyroY();

int16_t getGyroZ();

int16_t getTemperature();

;

IMU imu;

void setup()

Serial.begin(115200);

imu.init();

void loop()

imu.update();

// display tab-separated accel/gyro x/y/z values

Serial.print("a/g/t:\\t");

Serial.print(imu.getAccelX()); Serial.print("\\t");

Serial.print(imu.getAccelY()); Serial.print("\\t");

Serial.print(imu.getAccelZ()); Serial.print("\\t");

Serial.print(imu.getGyroX()); Serial.print("\\t");

Serial.print(imu.getGyroY()); Serial.print("\\t");

Serial.print(imu.getGyroZ()); Serial.print("\\t");

Serial.println(imu.getTemperature());

delay(100);

int IMU::init()

// initialize i2c

Wire.begin();

Wire.setClock(400000);

// initialize device

Serial.println("Initializing I2C devices...");

imu.initialize();

// verify connection

Serial.println("Testing device connections...");

if (imu.testConnection())

Serial.println("MPU6050 connection successful");

return 0;

else

Serial.println("MPU6050 connection failed");

return -1;

void IMU::update()

// read raw accel/gyro measurements from device

imu.getMotion6(&ax, &ay, &az, &gx, &gy, &gz);

// read temperature

temperature = imu.getTemperature();

int16_t IMU::getAccelX()

return ax;

int16_t IMU::getAccelY()

return ay;

int16_t IMU::getAccelZ()

return az;

int16_t IMU::getGyroX()

return gx;

int16_t IMU::getGyroY()

return gy;

int16_t IMU::getGyroZ()

return gz;

int16_t IMU::getTemperature()

return temperature;

3. 测试结果

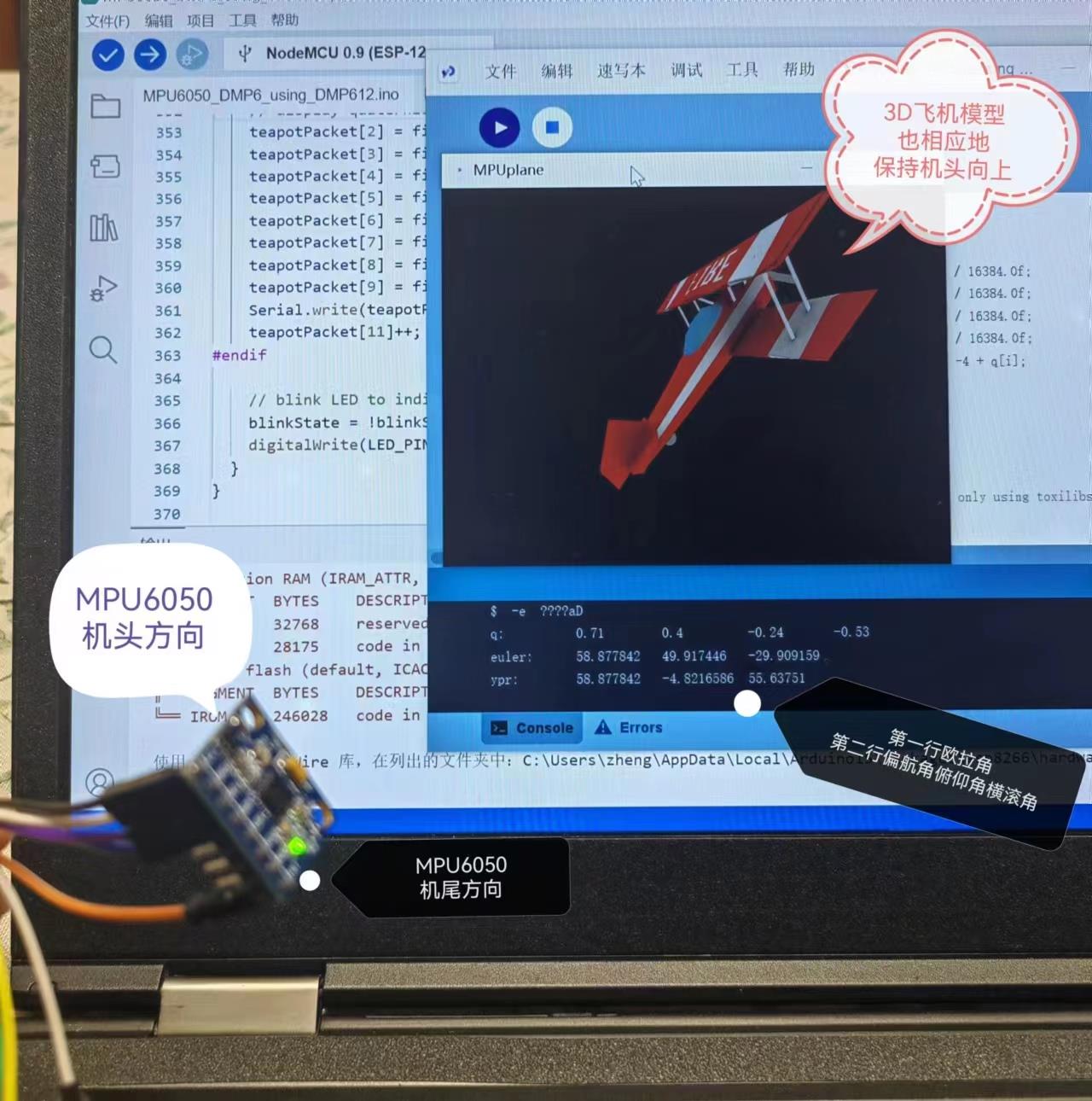

四、获取MPU6050 DMP姿态解算数据

1. 姿态解算

2. 硬件连接

添加 引脚GPIO16用来连接MPU6050中断引脚:

3. 代码编写

#include <Arduino.h>

#include "I2Cdev.h"

#include "MPU6050_6Axis_MotionApps20.h"

#include "Wire.h"

#define INTERRUPT_PIN 16

class IMU

private:

MPU6050 imu;

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

int16_t temperature;

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

public:

int init(uint8_t pin);

void update();

float getYaw();

float getPitch();

float getRoll();

int16_t getTemperature();

;

IMU imu;

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady()

mpuInterrupt = true;

void setup()

Serial.begin(115200);

imu.init(INTERRUPT_PIN);

void loop()

imu.update();

Serial.print("ypr\\t");

Serial.print(imu.getYaw());

Serial.print("\\t");

Serial.print(imu.getPitch());

Serial.print("\\t");

Serial.println(imu.getRoll());

delay(100);

int IMU::init(uint8_t pin)

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

// initialize i2c

Wire.begin();

Wire.setClock(400000);

// initialize device

Serial.println("Initializing I2C devices...");

imu.initialize();

// verify connection

Serial.println("Testing device connections...");

if (imu.testConnection())

Serial.println("MPU6050 connection successful");

else

Serial.println("MPU6050 connection failed");

return -1;

pinMode(pin, INPUT);

// load and configure the DMP

devStatus = imu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

imu.setXGyroOffset(220);

imu.setYGyroOffset(76);

imu.setZGyroOffset(-85);

imu.setZAccelOffset(1788); // 1688 factory default for my test chip

// make sure it worked (returns 0 if so)

if (devStatus == 0)

// Calibration Time: generate offsets and calibrate our MPU6050

imu.CalibrateAccel(6);

imu.CalibrateGyro(6);

imu.PrintActiveOffsets();

// turn on the DMP, now that it's ready

Serial.println(F("Enabling DMP..."));

imu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.print(F("Enabling interrupt detection (Arduino external interrupt "));

Serial.print(digitalPinToInterrupt(INTERRUPT_PIN));

Serial.println(F(")..."));

attachInterrupt(digitalPinToInterrupt(INTERRUPT_PIN), dmpDataReady, RISING);

mpuIntStatus = imu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it's okay to use it

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = imu.dmpGetFIFOPacketSize();

else

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it's going to break, usually the code will be 1)

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

void IMU::update()

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

// MPU control/status vars

uint8_t fifoBuffer[64]; // FIFO storage buffer

// if programming failed, don't try to do anything

if (!dmpReady) return;

// read a packet from FIFO

if (imu.dmpGetCurrentFIFOPacket(fifoBuffer)) // Get the Latest packet

// display Euler angles in degrees

imu.dmpGetQuaternion(&q, fifoBuffer);

imu.dmpGetGravity(&gravity, &q);

imu.dmpGetYawPitchRoll(ypr, &q, &gravity);

// read temperature

temperature = imu.getTemperature();

float IMU::getYaw()

return ypr[0] * 180/M_PI;

float IMU::getPitch()

return ypr[1] * 180/M_PI;

float IMU::getRoll()

return ypr[2] * 180/M_PI;

int16_t IMU::getTemperature()

return temperature;

4. 测试结果

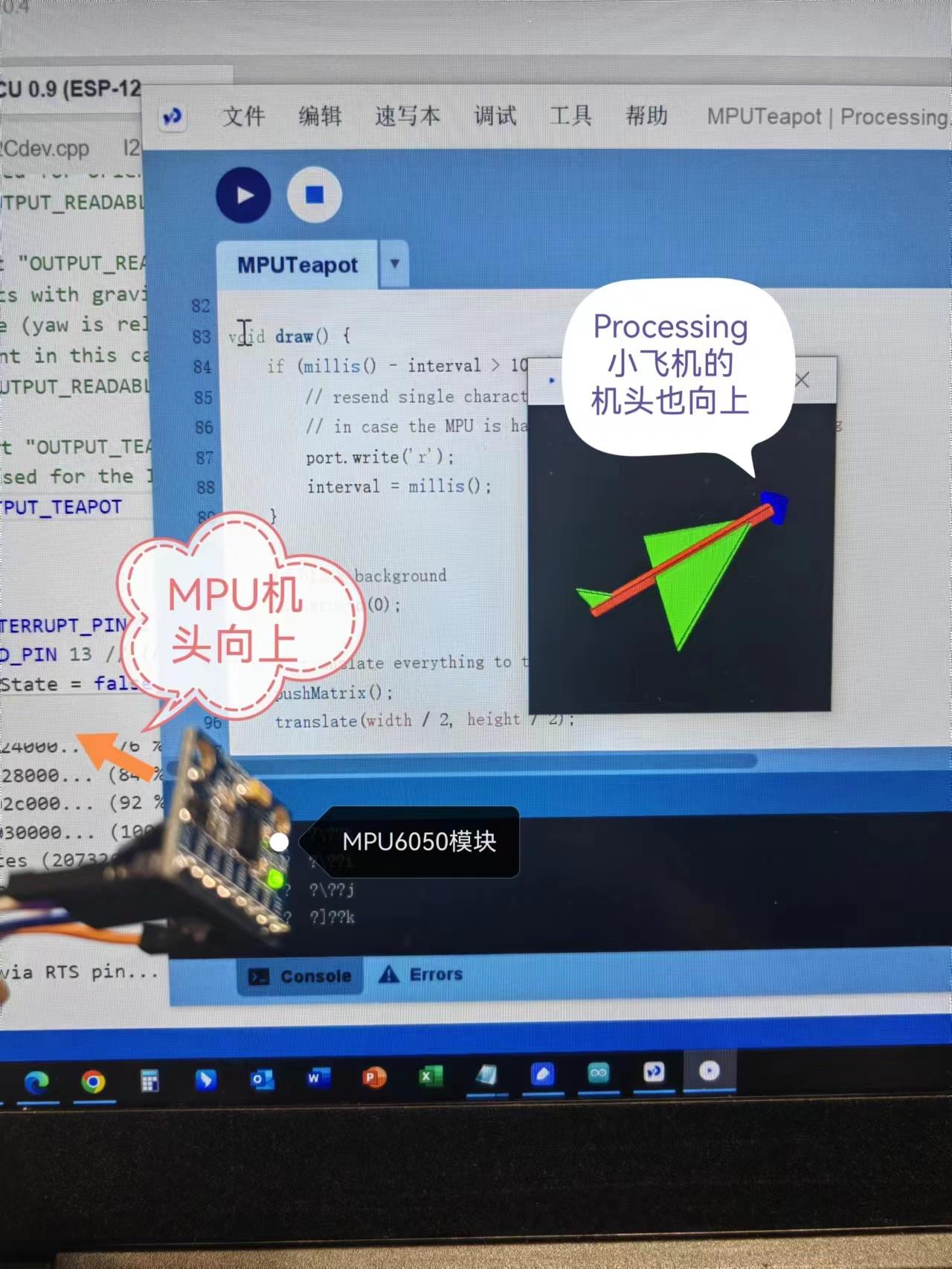

五、使用Processing进行姿态可视化

1. 安装Processing

下载地址:https://processing.org/download。

2. 安装toxiclibs库

3. 修改数据打印格式

添加格式定义:

// packet structure for InvenSense teapot demo

uint8_t teapotPacket[14] = '$', 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, '\\r', '\\n' ;

删除之前的打印格式:

Serial.print("ypr\\t");

Serial.print(imu.getYaw());

Serial.print("\\t");

Serial.print(imu.getPitch());

Serial.print("\\t");

Serial.println(imu.getRoll());

新增一个IMU类的发送数据函数:

void IMU::sendDataToProcessing()

// display quaternion values in InvenSense Teapot demo format:

teapotPacket[2] = fifoBuffer[0];

teapotPacket[3] = fifoBuffer[1];

teapotPacket[4] = fifoBuffer[4];

teapotPacket[5] = fifoBuffer[5];

teapotPacket[6] = fifoBuffer[8];

teapotPacket[7] = fifoBuffer[9];

teapotPacket[8] = fifoBuffer[12];

teapotPacket[9] = fifoBuffer[13];

Serial.write(teapotPacket, 14);

teapotPacket[11]++; // packetCount, loops at 0xFF on purpose

在update函数调用之后,调用该函数发送数据到上位机。

修改完毕,烧录代码。

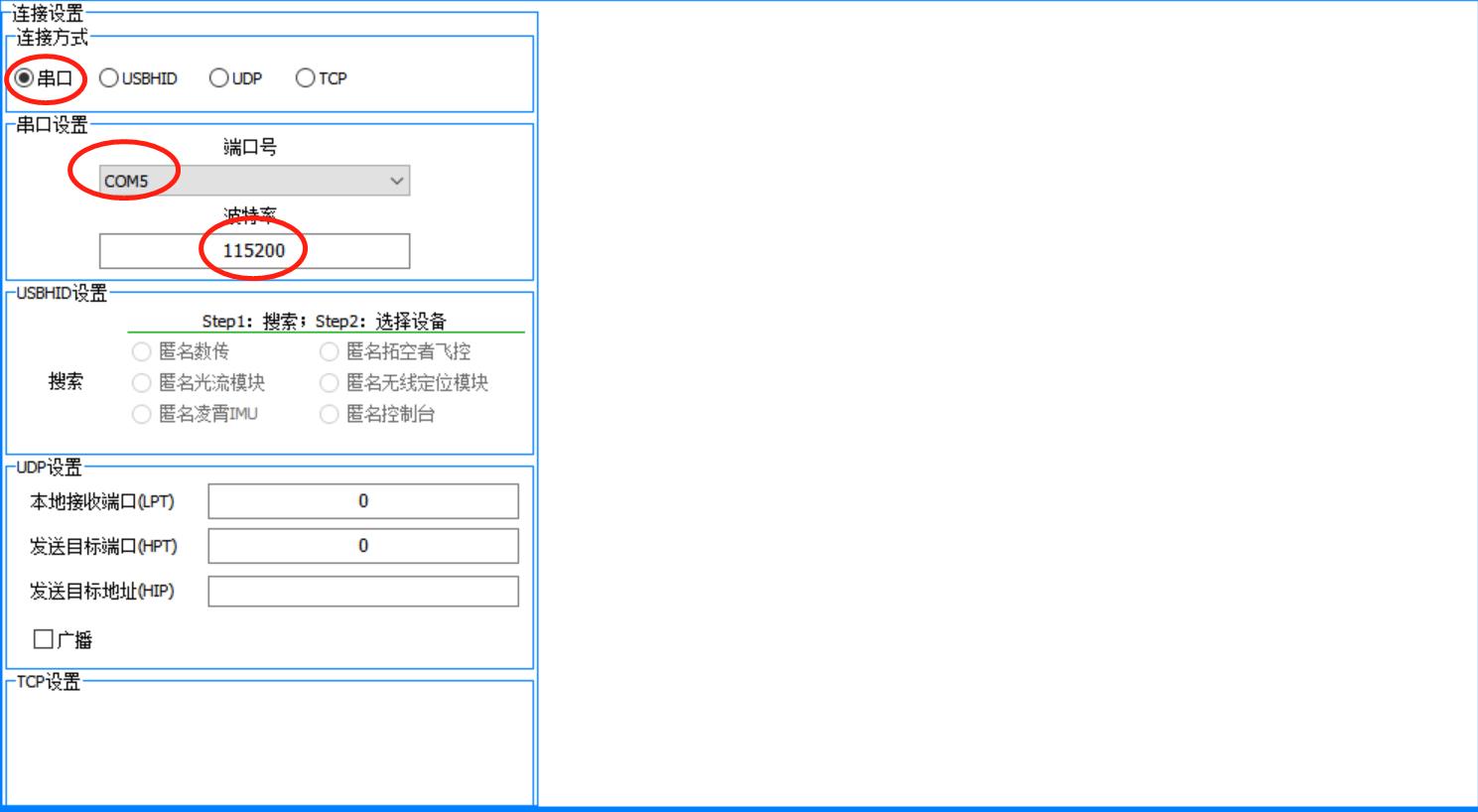

4. 运行processing上位机

上位机为lib\\MPU6050\\examples\\MPU6050_DMP6\\Processing\\MPUTeapot\\MPUTeapot.pde,使用processing打开。

修改连接ESP32的串口:

以上是关于MPU6050陀螺仪与Processing和上位机飞控联动实录的主要内容,如果未能解决你的问题,请参考以下文章