十分钟快速自制CMSIS_DAP仿真器,将ST-LINK-V2变身DAP仿真器!

Posted y-zheng

tags:

篇首语:本文由小常识网(cha138.com)小编为大家整理,主要介绍了十分钟快速自制CMSIS_DAP仿真器,将ST-LINK-V2变身DAP仿真器!相关的知识,希望对你有一定的参考价值。

十分钟快速自制CMSIS_DAP仿真器,将ST-LINK-V2变身DAP仿真器!

(一)简介

说到单片机仿真器(下载器)首先想到的就是J-LINK和ST-LINK,很多人可能还是第一次听说DAP仿真器,那么就先介绍一下。

CMSIS DAP是ARM官方推出的开源仿真器,支持所有的Cortex-A/R/M器件,支持JTAG/SWD接口。有以下特点:

- 完全开源,没有版权限制,所以相应的价格会很便宜

- 不需要安装驱动,即插即用

- 在新版本的DAP里集成了串口,除了下载调试外还能充当USB转串口模块,一机两用

- 性能方面已经可以满足一般用户的需求

市面上基本所有的离线下载器基本都是基于CMSIS_DAP方案来的,例如正点原子的离线下载器、无线下载器等,还有就是国产单片机厂家做的调试器,例如GD32出的GD-LINK,都是基于CMSIS DAP方案改的。

而ST-LINK是ST官方出的,目前有V1、V2、V3版本,并且闭源,正版的很贵!你买到的很便宜,可能也就十几三十几块钱得样子,这是因为这都是盗版的!网上早就有人把ST-LINK-V2的固件给破解出来的,而且原理图也有,所以市面上的便宜货都是根据官方的原理图做出来的板子,然后下载进固件就完成了一个ST-LINK调试器!但是他们是没有ST-LINK的固件源代码的!

什么是在线调试下载?

在线调试器就是用keil或者iar等软件对目标MCU进行调试和下载程序,适用于开发阶段。像是ST-LINK、J-LINK就是在线调试器。

什么是离线下载?

当项目开发中已经接近尾声或者已经成熟后,那么每生产一块板子就需要刷程序,但是刷程序就需要连接到PC机上通过软件刷,这样的话就非常的麻烦,那么有没有一种方式是做一个小板子,把下载程序的功能集成到这个小板子中,这样的话刷程序就是用这个小板子给目标MCU刷程序,就是手持式的。

有!就是离线下载器!

离线下载器的功能说简单点就是Keil下载程序的功能!

关于本篇

教程持续更新,最终的目的是做一个在线调试+离线下载完整功能的仿真器。

本篇教程就先实现用keil能够在线调试下载程序和调试的功能,这是实现完整功能最简单的一步。

(二)调试器的原理

在教程开始之前,我觉得有必要说一下调试器的原理以及他是怎么工作的,怎么把程序下载到目标MCU的,这里以KEIL+ST-LINK为例进行说明。

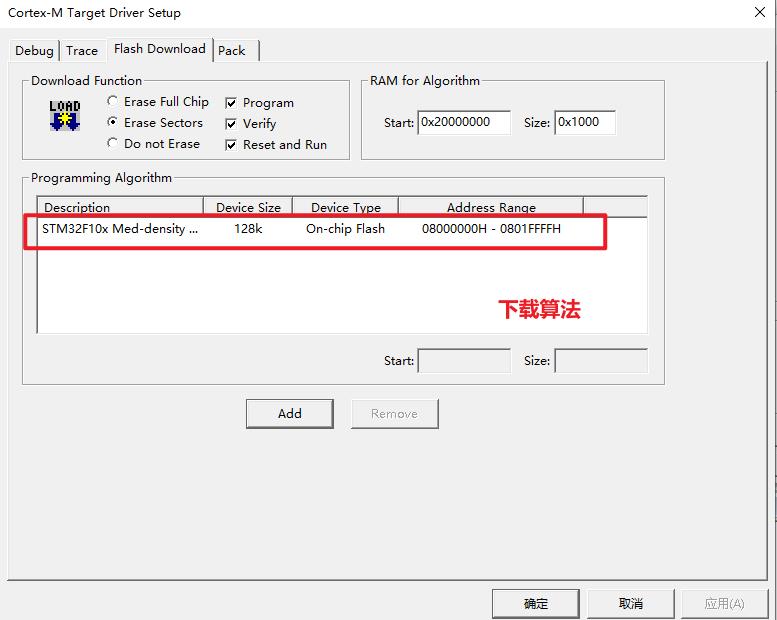

我们使用keil下载程序的时候,必须要选定一个下载算法,如下所示:

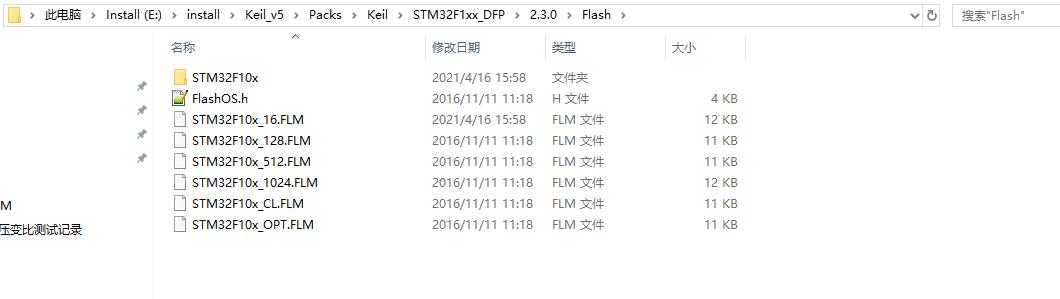

当你使用STM32的时候必须要安装pack包,而下载算法就在pack包内,安装好后就在keil软件的安装目录下了,具体在这里:

Keil会根据你当前工程使用的芯片,自动去识别应该用哪一个下载算法,例如我目前这个工程是用的STM32F103C8这个芯片,FLASH容量是64K的,属于这个系列的小容量,那么KEIL就自动给我识别了STM32F103x_128.FLM这个下载算法。

那么这个下载算法是什么东西?

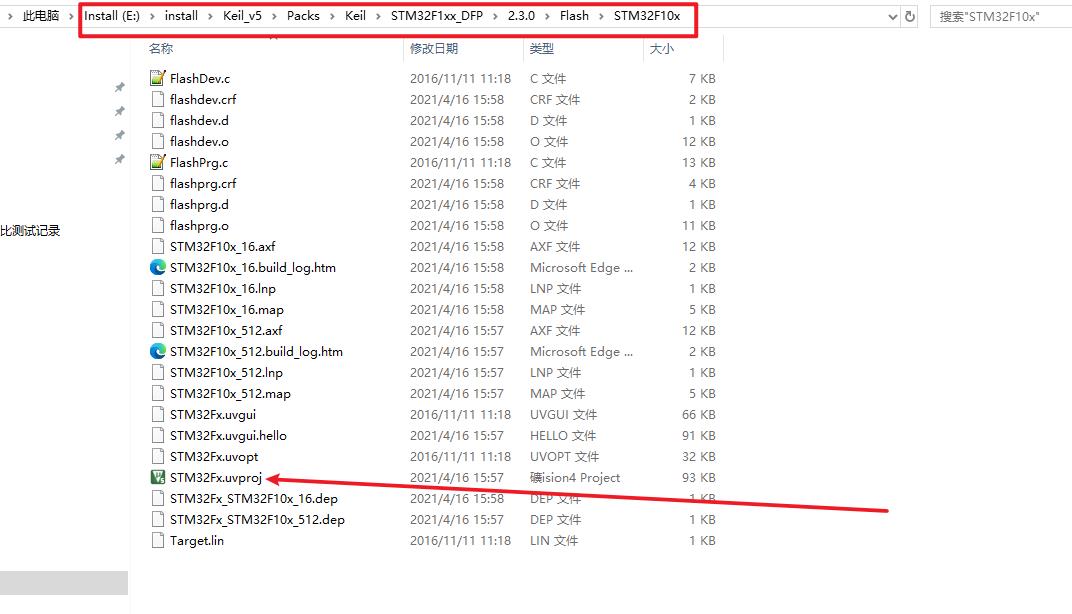

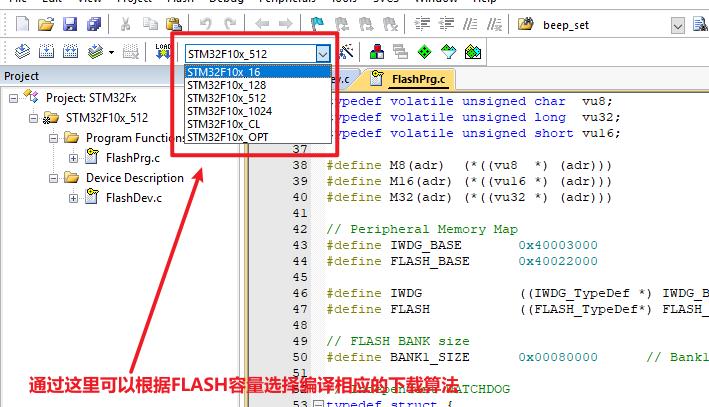

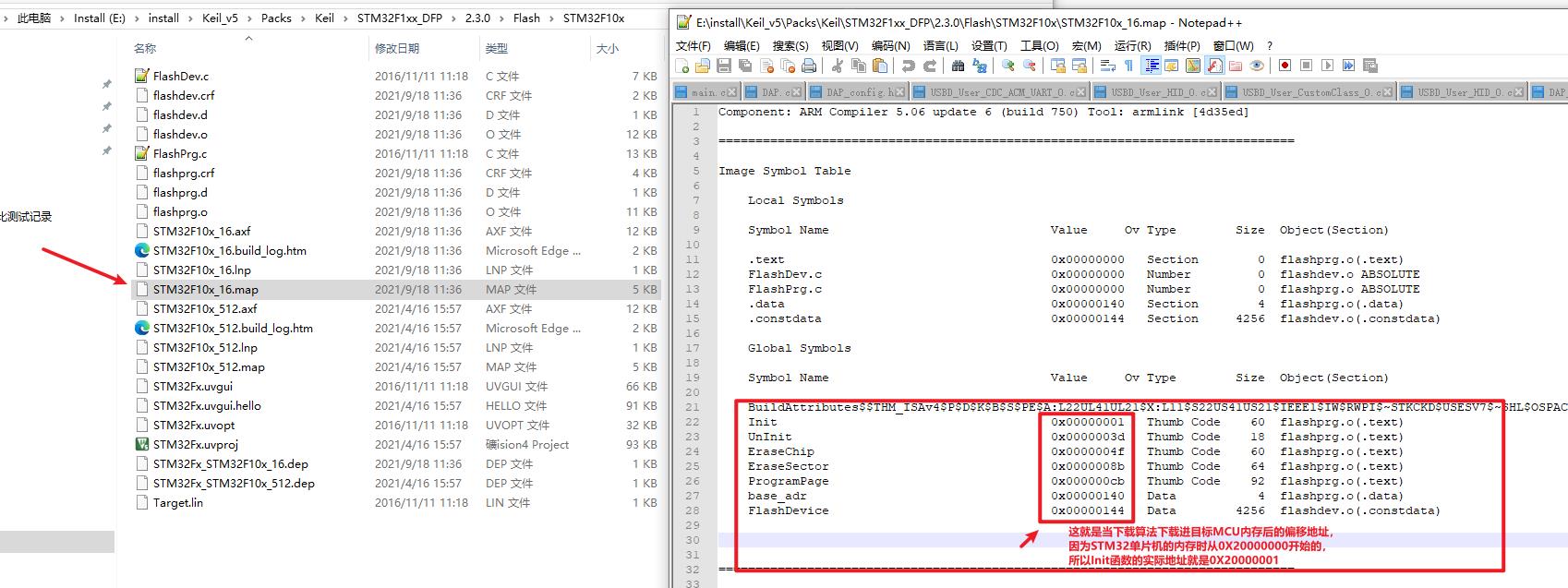

进入这个目录后,他有一个工程,而这个工程就是下载算法的模板工程,我们打开看一下:

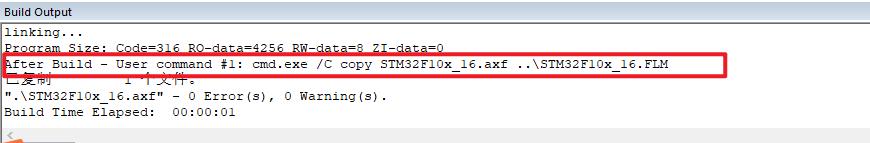

打开工程后很简单的,就只有两个文件,函数也很简单都是对FLASH的操作,编译一下看看:

AXF(ARM Executable File)是ARM芯片使用的文件格式,它除了包含bin代码外,还包括了输出给调试器的调试信息

看到没!编译完了之后生成了STM32F103x_16.axf文件,然后只是做了一个文件复制并且重命名成了STM32F10x_16.FLM文件!

现在对下载算法就明确了,下载算法其实就是对目标MCU的FLASH的一系列操作函数!

那么KEIL给目标MCU下载程序的时候,其实就是解析出编译好的.axf文件,然后通过USB连接线经过ST-LINK先将下载算法加载进目标MCU的内存中并运行,由于.axf文件中包含的信息很多,其中就有当程序加载进内存后函数在内存中的地址,这个地址也可以通过.map文件查看(.map文件也是keil在编译完工程后生成的),知道函数在内存中的地址,就可以在外部通过特定的进行调用,所以STLINK就是接收来自KEIL的固件程序,然后操控目标单片机内存中的FLASH的操作函数,在通过SWD协议将固件下载进目标MCU的FLASH中,就这样实现了程序下载,后面我们会做离线下载器那么也就明确了,可以将接收KEIL的下发固件这一个步骤变成本地SD卡存储固件,这样不就实现了离线~

现在keil整个下载程序的流程清楚了后,我们的CMSIS_DAP就可以分成两步骤进行:

- 第一步:实现KEIL通过USB和DAP的通信

- 第二步:DAP通过SWD协议将收到固件下载进目标MCU

对于第一步,我们使用STM32CubeMX软件生成工程,然后对源码进行一个简单的修改就可以完成。如果你对USB没有一个充分的了解,本章教程可以先不用管为什么这么修改源代码,跟着步骤来即可,我的另一篇博客有对USB相关知识的扫盲,可以帮助你快速了解:https://blog.csdn.net/qq153471503/article/details/116053851

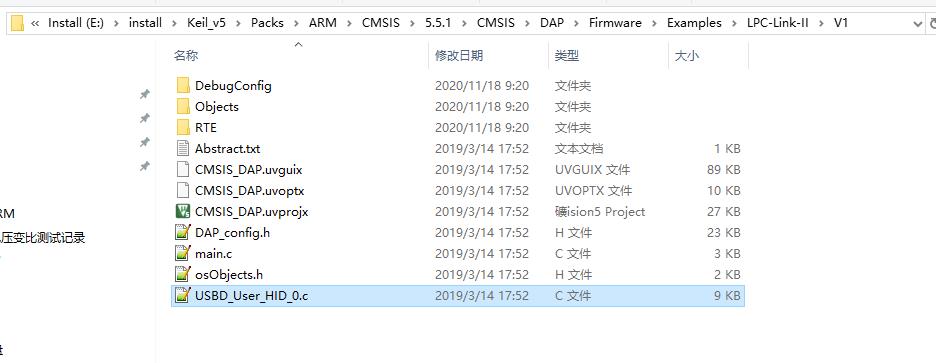

对于第二步,我们需要移植自ARM官方的CMSIS_DAP源码,源代码在Keil软件的安装目录下,ARM官方的代码是基于LPC单片机的,但是不妨碍我们移植使用:

我们需要的就是上图中这三个文件夹中的源文件以及USBD_User_HID_0.c文件即可,这个文件在这里:

(三)工程配置

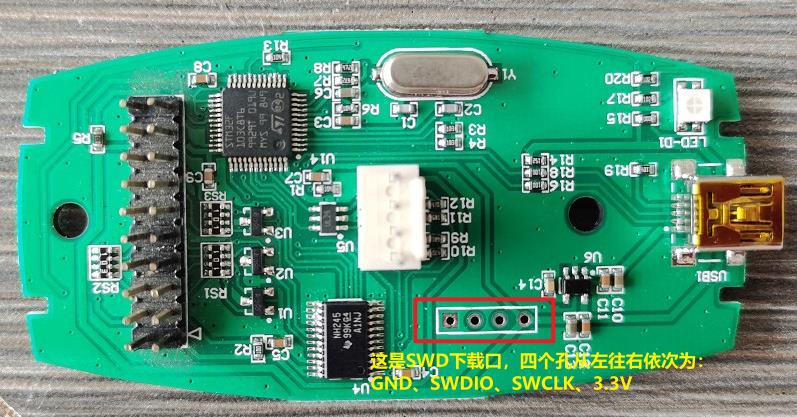

紧接上文,现在开始实现第一步,由于我目前手头没有现成的硬件,然后我想起ST-LINK其实也是个STM32F103C8单片机,那么我用STLINK的板子不就行了,而且在网上还能找到原理图,省去了自己做板子验证的步骤,等软件调试完毕后,在做板子把它做得小巧精致些。

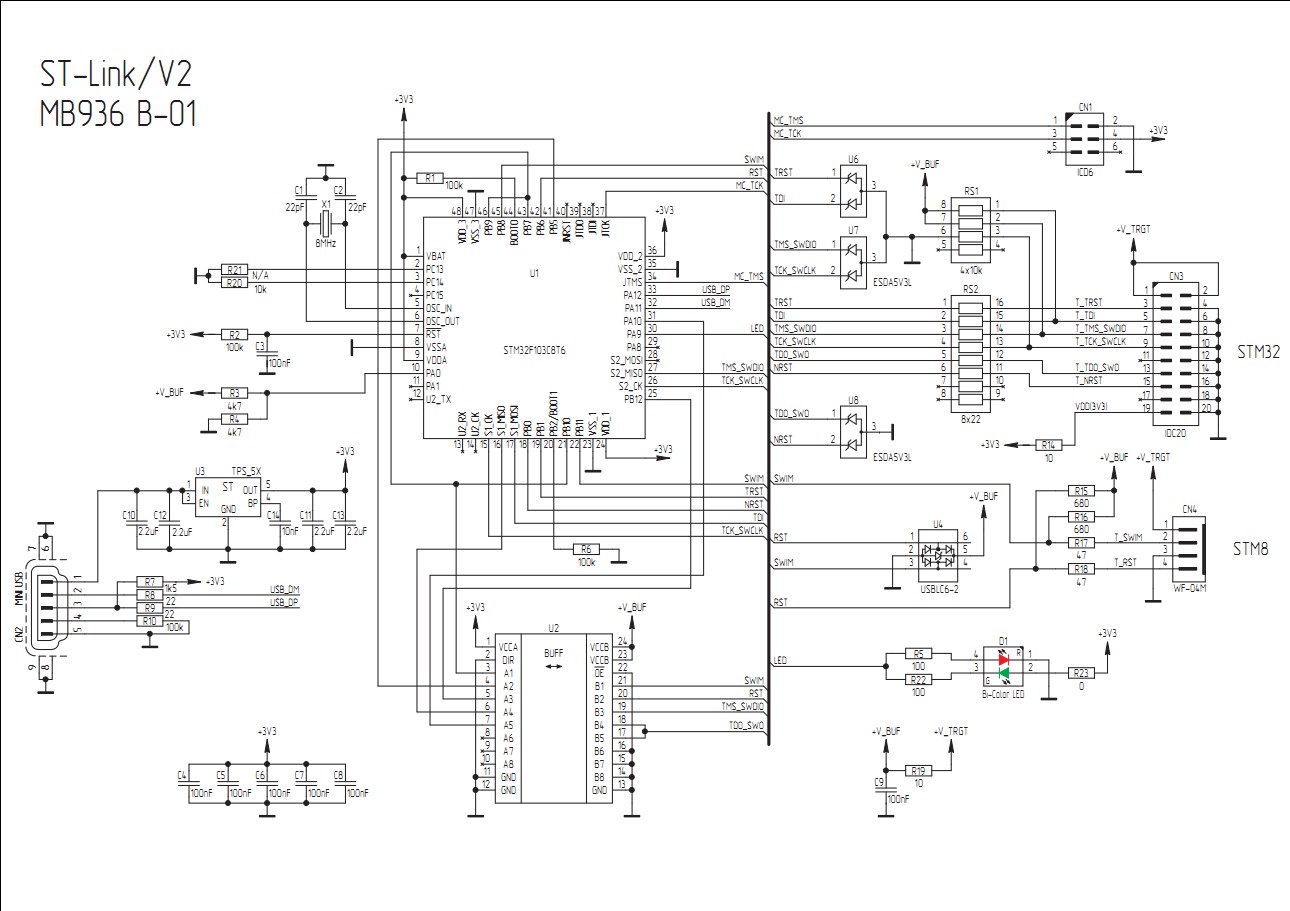

它的原理图是这样的:

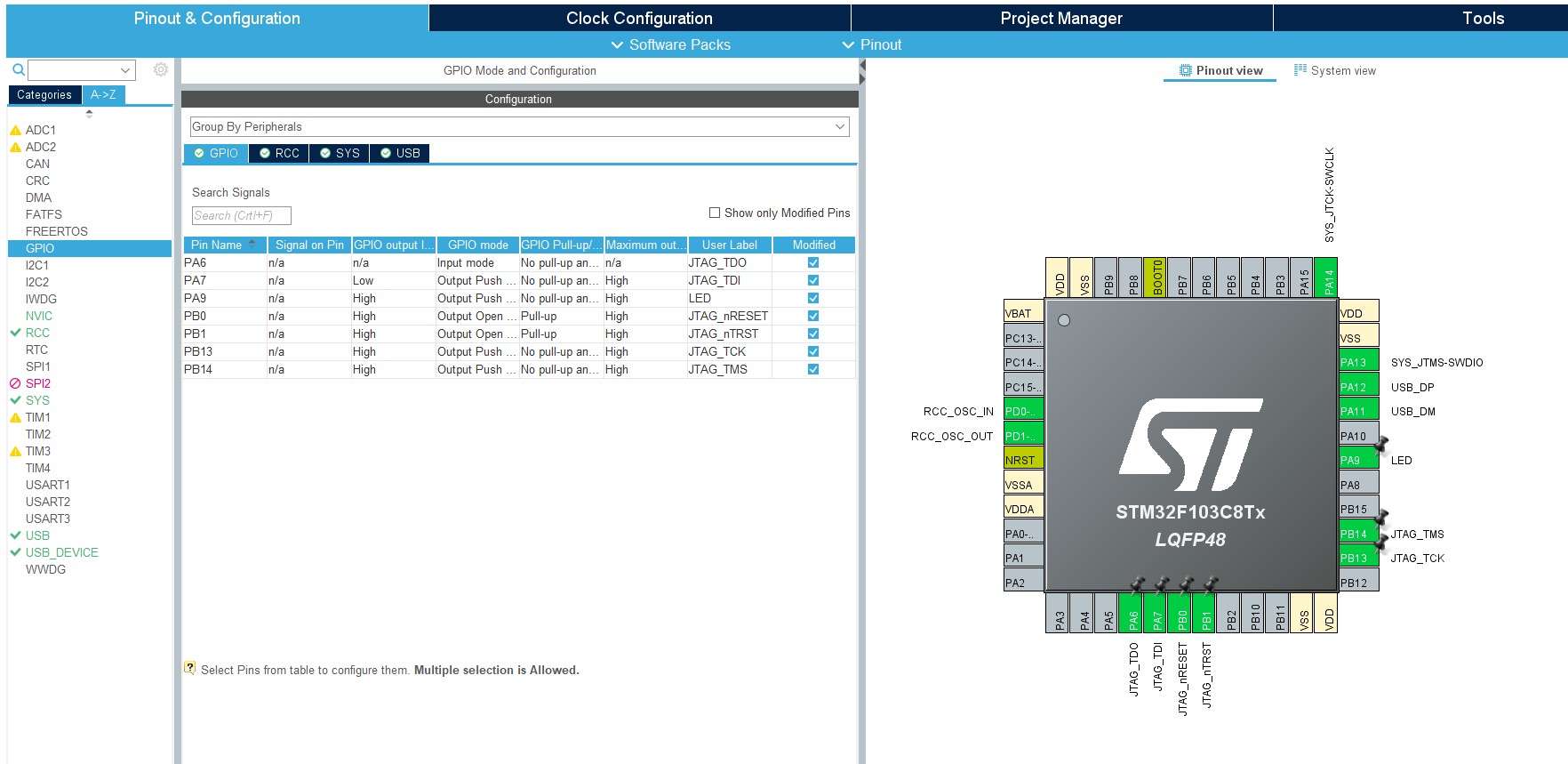

从原理图上可知,使用的引脚分布如下:

- JTAG_nTRST(PB1)

- JTAG_nRESET(PB0)

- JTAG_TDI(PA7)

- JTAG_TMS(PB14,这个引脚也是SWD模式下的SWDIO引脚)

- JTAG_TCK(PB13/PA5,这个引脚也是SWD模式下的SWCLK引脚)

- JTAG_TDO(PA6/PA10)

- LED灯(PA9,低电平为红灯,高电平为绿灯)

对于JTAG_TCK,这是时钟信号引脚,官方用了PB13和PA5两个引脚,我猜测是因为为了提高抗干扰能力,JTAG和SWD两种模式下,使用不同的引脚当做时钟信号。JTAG_TMS引脚同理。

对于JTAG_TDO,当JTAG模式时,这是JTAG的数据输入引脚,当使用SWD模式时,这个引脚可以作为调试输出的作用,所以也是分成了两个引脚来用。

在本教程中,我们就各只用一个IO就可以,不搞那么麻烦。

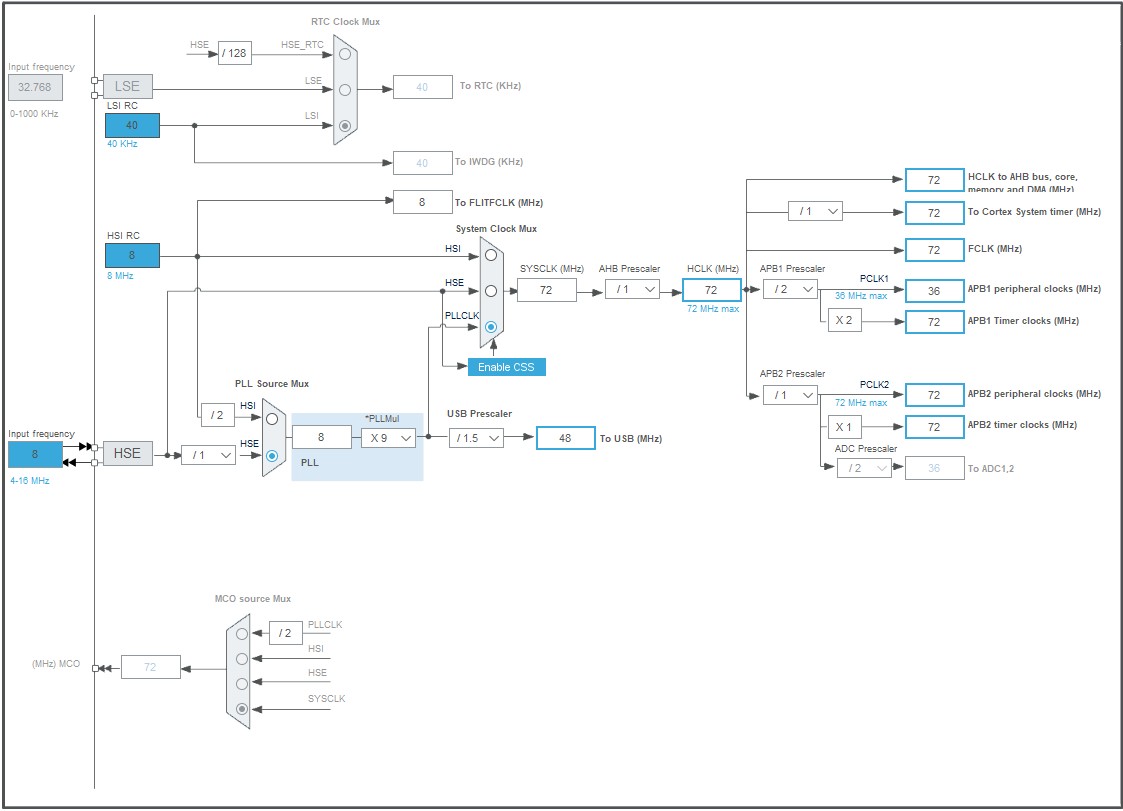

下面开始贴一下我的配置,时钟配置到72M,并开启USB配置成48M,如下:

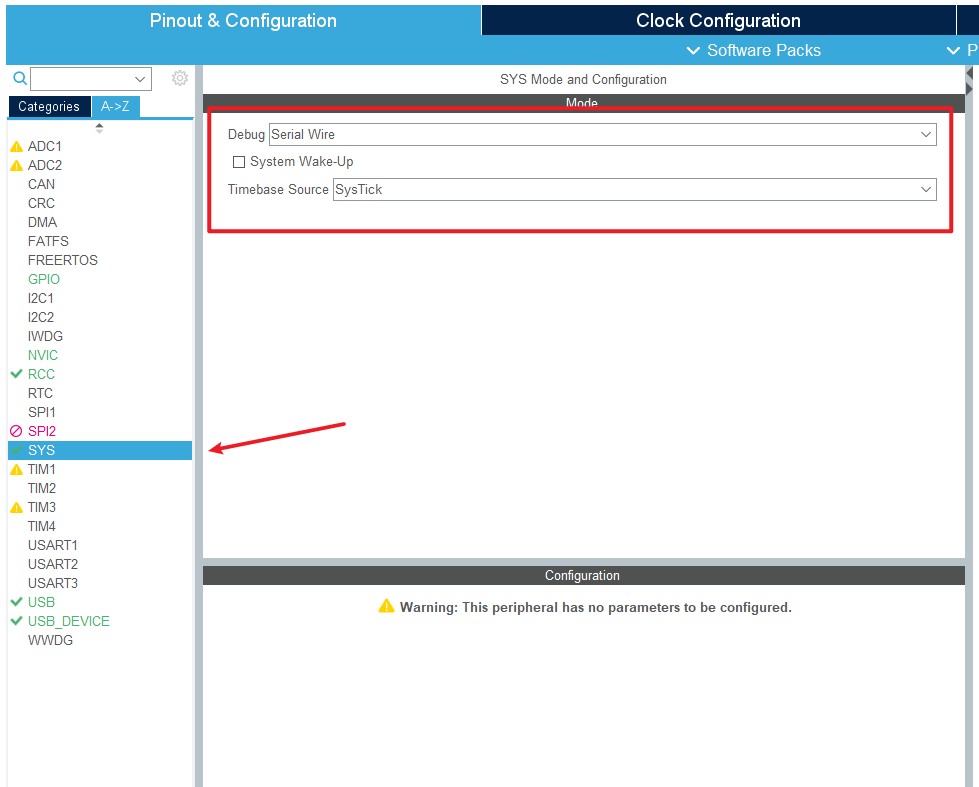

下载程序的调试接口配置为SWD模式:

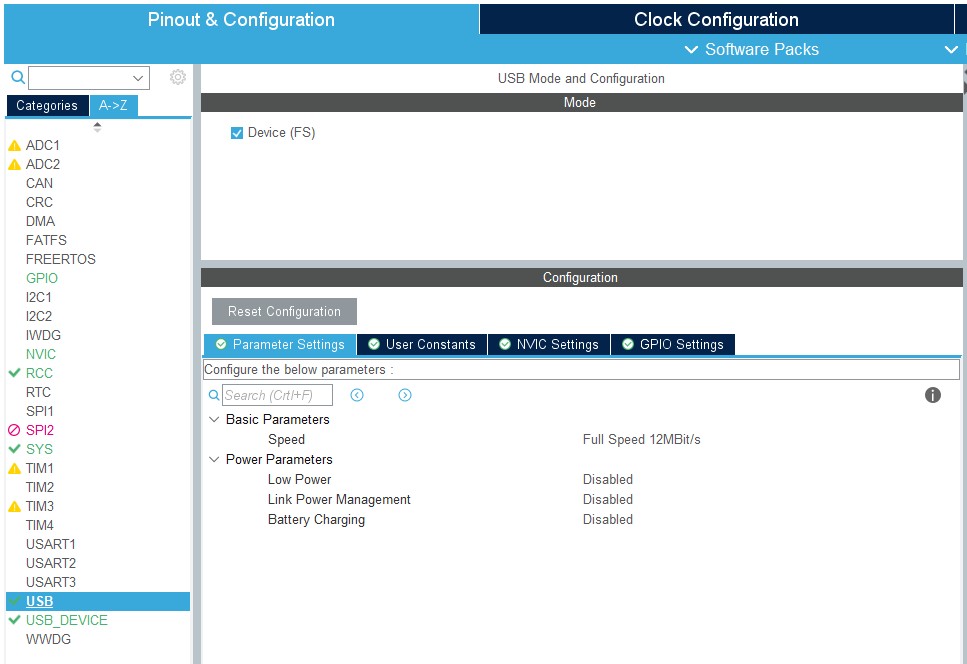

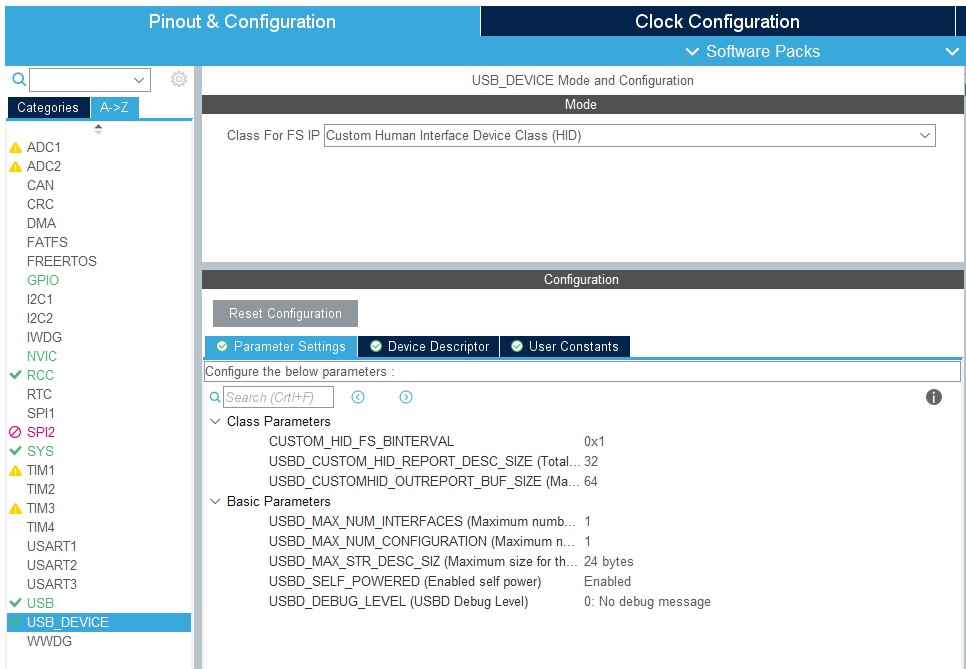

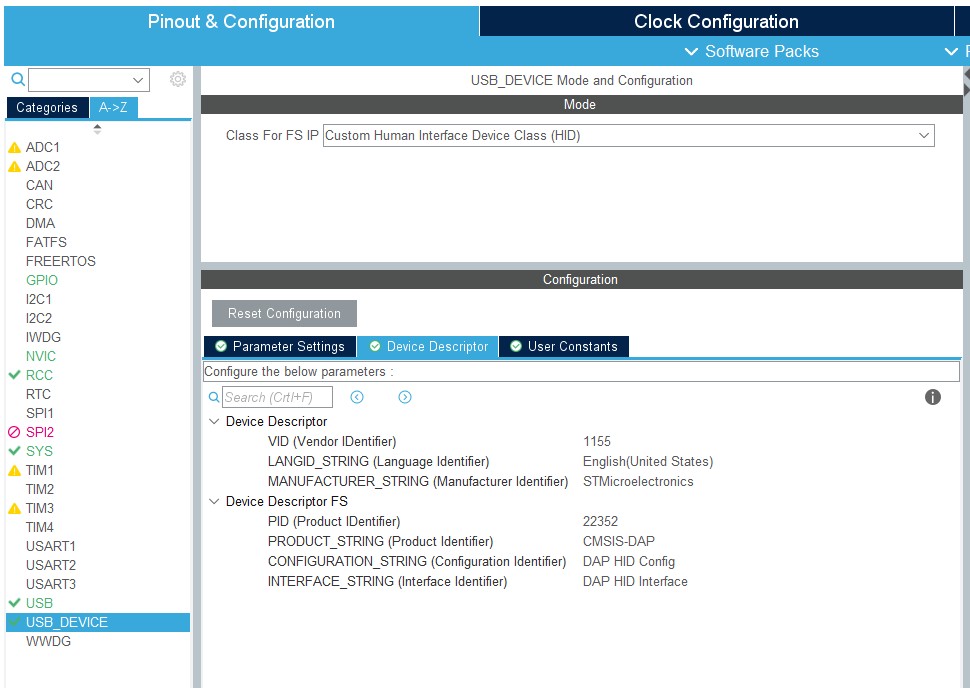

USB的配置如下:

IO引脚的配置如下:

这就是全部的配置内容,然后生成代码就可以了!

(四)移植DAP源码

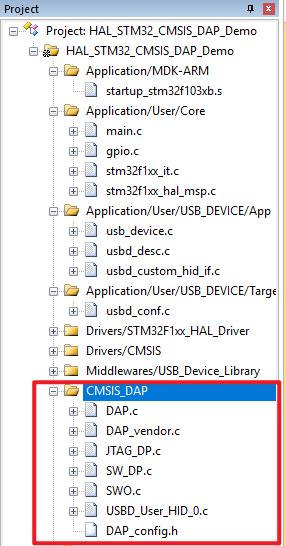

将DAP加入我们的工程,如下所示:

对于DAP源码的移植,我们主要就是修改DAP_config.h和USBD_User_HID_0.c俩文件,其中DAP_config.h是修改的GPIO以及DAP的一些默认配置参数,USBD_User_HID_0.c就是USB与PC的函数接口了,由于原CMSIS_DAP工程是基于LCP单片机并且跑了系统的,而我没有跑系统,所以就需要将USBD_User_HID_0.c文件中使用系统了的API换成轮训方式即可,下面贴一下我的配置:

DAP_config.h文件:

/*

* Copyright (c) 2013-2017 ARM Limited. All rights reserved.

*

* SPDX-License-Identifier: Apache-2.0

*

* Licensed under the Apache License, Version 2.0 (the License); you may

* not use this file except in compliance with the License.

* You may obtain a copy of the License at

*

* www.apache.org/licenses/LICENSE-2.0

*

* Unless required by applicable law or agreed to in writing, software

* distributed under the License is distributed on an AS IS BASIS, WITHOUT

* WARRANTIES OR CONDITIONS OF ANY KIND, either express or implied.

* See the License for the specific language governing permissions and

* limitations under the License.

*

* ----------------------------------------------------------------------

*

* $Date: 1. December 2017

* $Revision: V2.0.0

*

* Project: CMSIS-DAP Configuration

* Title: DAP_config.h CMSIS-DAP Configuration File (Template)

*

*---------------------------------------------------------------------------*/

#ifndef __DAP_CONFIG_H__

#define __DAP_CONFIG_H__

//**************************************************************************************************

/**

\\defgroup DAP_Config_Debug_gr CMSIS-DAP Debug Unit Information

\\ingroup DAP_ConfigIO_gr

@{

Provides definitions about the hardware and configuration of the Debug Unit.

This information includes:

- Definition of Cortex-M processor parameters used in CMSIS-DAP Debug Unit.

- Debug Unit Identification strings (Vendor, Product, Serial Number).

- Debug Unit communication packet size.

- Debug Access Port supported modes and settings (JTAG/SWD and SWO).

- Optional information about a connected Target Device (for Evaluation Boards).

*/

#include "main.h"

/// Processor Clock of the Cortex-M MCU used in the Debug Unit.

/// This value is used to calculate the SWD/JTAG clock speed.

#define CPU_CLOCK 72000000U ///< Specifies the CPU Clock in Hz.

/// Number of processor cycles for I/O Port write operations.

/// This value is used to calculate the SWD/JTAG clock speed that is generated with I/O

/// Port write operations in the Debug Unit by a Cortex-M MCU. Most Cortex-M processors

/// require 2 processor cycles for a I/O Port Write operation. If the Debug Unit uses

/// a Cortex-M0+ processor with high-speed peripheral I/O only 1 processor cycle might be

/// required.

#define IO_PORT_WRITE_CYCLES 2U ///< I/O Cycles: 2=default, 1=Cortex-M0+ fast I/0.

/// Indicate that Serial Wire Debug (SWD) communication mode is available at the Debug Access Port.

/// This information is returned by the command \\ref DAP_Info as part of <b>Capabilities</b>.

#define DAP_SWD 1 ///< SWD Mode: 1 = available, 0 = not available.

/// Indicate that JTAG communication mode is available at the Debug Port.

/// This information is returned by the command \\ref DAP_Info as part of <b>Capabilities</b>.

#define DAP_JTAG 1 ///< JTAG Mode: 1 = available, 0 = not available.

/// Configure maximum number of JTAG devices on the scan chain connected to the Debug Access Port.

/// This setting impacts the RAM requirements of the Debug Unit. Valid range is 1 .. 255.

#define DAP_JTAG_DEV_CNT 8U ///< Maximum number of JTAG devices on scan chain.

/// Default communication mode on the Debug Access Port.

/// Used for the command \\ref DAP_Connect when Port Default mode is selected.

#define DAP_DEFAULT_PORT 1U ///< Default JTAG/SWJ Port Mode: 1 = SWD, 2 = JTAG.

/// Default communication speed on the Debug Access Port for SWD and JTAG mode.

/// Used to initialize the default SWD/JTAG clock frequency.

/// The command \\ref DAP_SWJ_Clock can be used to overwrite this default setting.

#define DAP_DEFAULT_SWJ_CLOCK 10000000U ///< Default SWD/JTAG clock frequency in Hz.

/// Maximum Package Size for Command and Response data.

/// This configuration settings is used to optimize the communication performance with the

/// debugger and depends on the USB peripheral. Typical vales are 64 for Full-speed USB HID or WinUSB,

/// 1024 for High-speed USB HID and 512 for High-speed USB WinUSB.

#define DAP_PACKET_SIZE 64U ///< Specifies Packet Size in bytes.

/// Maximum Package Buffers for Command and Response data.

/// This configuration settings is used to optimize the communication performance with the

/// debugger and depends on the USB peripheral. For devices with limited RAM or USB buffer the

/// setting can be reduced (valid range is 1 .. 255).

#define DAP_PACKET_COUNT 8U ///< Specifies number of packets buffered.

/// Indicate that UART Serial Wire Output (SWO) trace is available.

/// This information is returned by the command \\ref DAP_Info as part of <b>Capabilities</b>.

#define SWO_UART 0 ///< SWO UART: 1 = available, 0 = not available.

/// Maximum SWO UART Baudrate.

#define SWO_UART_MAX_BAUDRATE 10000000U ///< SWO UART Maximum Baudrate in Hz.

/// Indicate that Manchester Serial Wire Output (SWO) trace is available.

/// This information is returned by the command \\ref DAP_Info as part of <b>Capabilities</b>.

#define SWO_MANCHESTER 0 ///< SWO Manchester: 1 = available, 0 = not available.

/// SWO Trace Buffer Size.

#define SWO_BUFFER_SIZE 4096U ///< SWO Trace Buffer Size in bytes (must be 2^n).

/// SWO Streaming Trace.

#define SWO_STREAM 0 ///< SWO Streaming Trace: 1 = available, 0 = not available.

/// Clock frequency of the Test Domain Timer. Timer value is returned with \\ref TIMESTAMP_GET.

#define TIMESTAMP_CLOCK 72000000U ///< Timestamp clock in Hz (0 = timestamps not supported).

/// Debug Unit is connected to fixed Target Device.

/// The Debug Unit may be part of an evaluation board and always connected to a fixed

/// known device. In this case a Device Vendor and Device Name string is stored which

/// may be used by the debugger or IDE to configure device parameters.

#define TARGET_DEVICE_FIXED 0 ///< Target Device: 1 = known, 0 = unknown;

#if TARGET_DEVICE_FIXED

#define TARGET_DEVICE_VENDOR "ARM" ///< String indicating the Silicon Vendor

#define TARGET_DEVICE_NAME "Cortex-M4" ///< String indicating the Target Device

#endif

/** Get Vendor ID string.

\\param str Pointer to buffer to store the string.

\\return String length.

*/

__STATIC_INLINE uint8_t DAP_GetVendorString (char *str)

{

(void)str;

return (0U);

}

/** Get Product ID string.

\\param str Pointer to buffer to store the string.

\\return String length.

*/

__STATIC_INLINE uint8_t DAP_GetProductString (char *str)

{

(void)str;

return (0U);

}

/** Get Serial Number string.

\\param str Pointer to buffer to store the string.

\\return String length.

*/

__STATIC_INLINE uint8_t DAP_GetSerNumString (char *str)

{

(void)str;

return (0U);

}

///@}

//**************************************************************************************************

/**

\\defgroup DAP_Config_PortIO_gr CMSIS-DAP Hardware I/O Pin Access

\\ingroup DAP_ConfigIO_gr

@{

Standard I/O Pins of the CMSIS-DAP Hardware Debug Port support standard JTAG mode

and Serial Wire Debug (SWD) mode. In SWD mode only 2 pins are required to implement the debug

interface of a device. The following I/O Pins are provided:

JTAG I/O Pin | SWD I/O Pin | CMSIS-DAP Hardware pin mode

---------------------------- | -------------------- | ---------------------------------------------

TCK: Test Clock | SWCLK: Clock | Output Push/Pull

TMS: Test Mode Select | SWDIO: Data I/O | Output Push/Pull; Input (for receiving data)

TDI: Test Data Input | | Output Push/Pull

TDO: Test Data Output | | Input

nTRST: Test Reset (optional) | | Output Open Drain with pull-up resistor

nRESET: Device Reset | nRESET: Device Reset | Output Open Drain with pull-up resistor

DAP Hardware I/O Pin Access Functions

-------------------------------------

The various I/O Pins are accessed by functions that implement the Read, Write, Set, or Clear to

these I/O Pins.

For the SWDIO I/O Pin there are additional functions that are called in SWD I/O mode only.

This functions are provided to achieve faster I/O that is possible with some advanced GPIO

peripherals that can independently write/read a single I/O pin without affecting any other pins

of the same I/O port. The following SWDIO I/O Pin functions are provided:

- \\ref PIN_SWDIO_OUT_ENABLE to enable the output mode from the DAP hardware.

- \\ref PIN_SWDIO_OUT_DISABLE to enable the input mode to the DAP hardware.

- \\ref PIN_SWDIO_IN to read from the SWDIO I/O pin with utmost possible speed.

- \\ref PIN_SWDIO_OUT to write to the SWDIO I/O pin with utmost possible speed.

*/

// Configure DAP I/O pins ------------------------------

/** Setup JTAG I/O pins: TCK, TMS, TDI, TDO, nTRST, and nRESET.

Configures the DAP Hardware I/O pins for JTAG mode:

- TCK, TMS, TDI, nTRST, nRESET to output mode and set to high level.

- TDO to input mode.

*/

__STATIC_INLINE void PORT_JTAG_SETUP (void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

__HAL_RCC_GPIOC_CLK_ENABLE();

HAL_GPIO_WritePin(LED_GPIO_Port, LED_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TCK_GPIO_Port, JTAG_TCK_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TMS_GPIO_Port, JTAG_TMS_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_nRESET_GPIO_Port, JTAG_nRESET_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TDI_GPIO_Port, JTAG_TDI_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TDO_GPIO_Port, JTAG_TDO_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_nTRST_GPIO_Port, JTAG_nTRST_Pin, GPIO_PIN_SET);

// LED

GPIO_InitStruct.Pin = LED_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(LED_GPIO_Port, &GPIO_InitStruct);

// TCK

GPIO_InitStruct.Pin = JTAG_TCK_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TCK_GPIO_Port, &GPIO_InitStruct);

// TMS

GPIO_InitStruct.Pin = JTAG_TMS_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TMS_GPIO_Port, &GPIO_InitStruct);

// TDI

GPIO_InitStruct.Pin = JTAG_TDI_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TDI_GPIO_Port, &GPIO_InitStruct);

// nRESET

GPIO_InitStruct.Pin = JTAG_nRESET_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_OD;

GPIO_InitStruct.Pull = GPIO_PULLUP;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_nRESET_GPIO_Port, &GPIO_InitStruct);

// nTRST

GPIO_InitStruct.Pin = JTAG_nTRST_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_OD;

GPIO_InitStruct.Pull = GPIO_PULLUP;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_nTRST_GPIO_Port, &GPIO_InitStruct);

// TDO

GPIO_InitStruct.Pin = JTAG_TDO_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_INPUT;

GPIO_InitStruct.Pull = GPIO_NOPULL;

HAL_GPIO_Init(JTAG_TDO_GPIO_Port, &GPIO_InitStruct);

}

/** Setup SWD I/O pins: SWCLK, SWDIO, and nRESET.

Configures the DAP Hardware I/O pins for Serial Wire Debug (SWD) mode:

- SWCLK, SWDIO, nRESET to output mode and set to default high level.

- TDI, nTRST to HighZ mode (pins are unused in SWD mode).

*/

__STATIC_INLINE void PORT_SWD_SETUP (void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

__HAL_RCC_GPIOA_CLK_ENABLE();

__HAL_RCC_GPIOB_CLK_ENABLE();

__HAL_RCC_GPIOC_CLK_ENABLE();

HAL_GPIO_WritePin(LED_GPIO_Port, LED_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TCK_GPIO_Port, JTAG_TCK_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TMS_GPIO_Port, JTAG_TMS_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_nRESET_GPIO_Port, JTAG_nRESET_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TDI_GPIO_Port, JTAG_TDI_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_TDO_GPIO_Port, JTAG_TDO_Pin, GPIO_PIN_SET);

HAL_GPIO_WritePin(JTAG_nTRST_GPIO_Port, JTAG_nTRST_Pin, GPIO_PIN_SET);

// LED

GPIO_InitStruct.Pin = LED_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(LED_GPIO_Port, &GPIO_InitStruct);

// TCK

GPIO_InitStruct.Pin = JTAG_TCK_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TCK_GPIO_Port, &GPIO_InitStruct);

// TMS

GPIO_InitStruct.Pin = JTAG_TMS_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TMS_GPIO_Port, &GPIO_InitStruct);

// nRESET

GPIO_InitStruct.Pin = JTAG_nRESET_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_OD;

GPIO_InitStruct.Pull = GPIO_PULLUP;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_nRESET_GPIO_Port, &GPIO_InitStruct);

// TDI TDO nTRST

HAL_GPIO_DeInit(JTAG_TDI_GPIO_Port, JTAG_TDI_Pin);

HAL_GPIO_DeInit(JTAG_TDO_GPIO_Port, JTAG_TDO_Pin);

HAL_GPIO_DeInit(JTAG_nTRST_GPIO_Port, JTAG_nTRST_Pin);

}

/** Disable JTAG/SWD I/O Pins.

Disables the DAP Hardware I/O pins which configures:

- TCK/SWCLK, TMS/SWDIO, TDI, TDO, nTRST, nRESET to High-Z mode.

*/

__STATIC_INLINE void PORT_OFF (void)

{

HAL_GPIO_DeInit(JTAG_TCK_GPIO_Port, JTAG_TCK_Pin);

HAL_GPIO_DeInit(JTAG_TMS_GPIO_Port, JTAG_TMS_Pin);

HAL_GPIO_DeInit(JTAG_nRESET_GPIO_Port, JTAG_nRESET_Pin);

HAL_GPIO_DeInit(JTAG_TDI_GPIO_Port, JTAG_TDI_Pin);

HAL_GPIO_DeInit(JTAG_TDO_GPIO_Port, JTAG_TDO_Pin);

HAL_GPIO_DeInit(JTAG_nTRST_GPIO_Port, JTAG_nTRST_Pin);

}

// SWCLK/TCK I/O pin -------------------------------------

/** SWCLK/TCK I/O pin: Get Input.

\\return Current status of the SWCLK/TCK DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE uint32_t PIN_SWCLK_TCK_IN (void)

{

return JTAG_TCK_GPIO_Port->ODR & JTAG_TCK_Pin ? 1 : 0;

}

/** SWCLK/TCK I/O pin: Set Output to High.

Set the SWCLK/TCK DAP hardware I/O pin to high level.

*/

__STATIC_FORCEINLINE void PIN_SWCLK_TCK_SET (void)

{

JTAG_TCK_GPIO_Port->BSRR = JTAG_TCK_Pin;

}

/** SWCLK/TCK I/O pin: Set Output to Low.

Set the SWCLK/TCK DAP hardware I/O pin to low level.

*/

__STATIC_FORCEINLINE void PIN_SWCLK_TCK_CLR (void)

{

JTAG_TCK_GPIO_Port->BRR = JTAG_TCK_Pin;

}

// SWDIO/TMS Pin I/O --------------------------------------

/** SWDIO/TMS I/O pin: Get Input.

\\return Current status of the SWDIO/TMS DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE uint32_t PIN_SWDIO_TMS_IN (void)

{

return JTAG_TMS_GPIO_Port->ODR & JTAG_TMS_Pin ? 1 : 0;

}

/** SWDIO/TMS I/O pin: Set Output to High.

Set the SWDIO/TMS DAP hardware I/O pin to high level.

*/

__STATIC_FORCEINLINE void PIN_SWDIO_TMS_SET (void)

{

JTAG_TMS_GPIO_Port->BSRR = JTAG_TMS_Pin;

}

/** SWDIO/TMS I/O pin: Set Output to Low.

Set the SWDIO/TMS DAP hardware I/O pin to low level.

*/

__STATIC_FORCEINLINE void PIN_SWDIO_TMS_CLR (void)

{

JTAG_TMS_GPIO_Port->BRR = JTAG_TMS_Pin;

}

/** SWDIO I/O pin: Get Input (used in SWD mode only).

\\return Current status of the SWDIO DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE uint32_t PIN_SWDIO_IN (void)

{

return JTAG_TMS_GPIO_Port->IDR & JTAG_TMS_Pin ? 1 : 0;

}

/** SWDIO I/O pin: Set Output (used in SWD mode only).

\\param bit Output value for the SWDIO DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE void PIN_SWDIO_OUT (uint32_t bit)

{

if(bit & 0X01)

{

JTAG_TMS_GPIO_Port->BSRR = JTAG_TMS_Pin;

}

else

{

JTAG_TMS_GPIO_Port->BRR = JTAG_TMS_Pin;

}

}

/** SWDIO I/O pin: Switch to Output mode (used in SWD mode only).

Configure the SWDIO DAP hardware I/O pin to output mode. This function is

called prior \\ref PIN_SWDIO_OUT function calls.

*/

__STATIC_FORCEINLINE void PIN_SWDIO_OUT_ENABLE (void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

GPIO_InitStruct.Pin = JTAG_TMS_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_OUTPUT_PP;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TMS_GPIO_Port, &GPIO_InitStruct);

}

/** SWDIO I/O pin: Switch to Input mode (used in SWD mode only).

Configure the SWDIO DAP hardware I/O pin to input mode. This function is

called prior \\ref PIN_SWDIO_IN function calls.

*/

__STATIC_FORCEINLINE void PIN_SWDIO_OUT_DISABLE (void)

{

GPIO_InitTypeDef GPIO_InitStruct = {0};

GPIO_InitStruct.Pin = JTAG_TMS_Pin;

GPIO_InitStruct.Mode = GPIO_MODE_INPUT;

GPIO_InitStruct.Pull = GPIO_NOPULL;

GPIO_InitStruct.Speed = GPIO_SPEED_FREQ_HIGH;

HAL_GPIO_Init(JTAG_TMS_GPIO_Port, &GPIO_InitStruct);

}

// TDI Pin I/O ---------------------------------------------

/** TDI I/O pin: Get Input.

\\return Current status of the TDI DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE uint32_t PIN_TDI_IN (void)

{

return JTAG_TDI_GPIO_Port->ODR & JTAG_TDI_Pin ? 1 : 0;

}

/** TDI I/O pin: Set Output.

\\param bit Output value for the TDI DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE void PIN_TDI_OUT (uint32_t bit)

{

if(bit & 0X01)

{

JTAG_TDI_GPIO_Port->BSRR = JTAG_TDI_Pin;

}

else

{

JTAG_TDI_GPIO_Port->BRR = JTAG_TDI_Pin;

}

}

// TDO Pin I/O ---------------------------------------------

/** TDO I/O pin: Get Input.

\\return Current status of the TDO DAP hardware I/O pin.

*/

__STATIC_FORCEINLINE uint32_t PIN_TDO_IN (void)

{

return JTAG_TDO_GPIO_Port->IDR & JTAG_TDO_Pin ? 1 : 0<以上是关于十分钟快速自制CMSIS_DAP仿真器,将ST-LINK-V2变身DAP仿真器!的主要内容,如果未能解决你的问题,请参考以下文章